Sputtering Equipment Cathode Market Size - Global Industry, Share, Analysis, Trends and Forecast 2024 - 2032

Published :

Report ID:

Pages :

Format :

Sputtering Equipment Cathode Market Size - Global Industry, Share, Analysis, Trends and Forecast 2024 - 2032

Report Coverage

- Industry Dynamics

- Market Size and Forecast Data

- Segment Analysis

- Competitive Landscape

- Regional Analysis with a Niche Focus on Country-Level Data

- High Level Analysis - Porter's, PESTEL, Value Chain, etc.

- Company Profiles of Key Players

- Option to Customize the Report As Per Your Specific Need

Request Sample Report

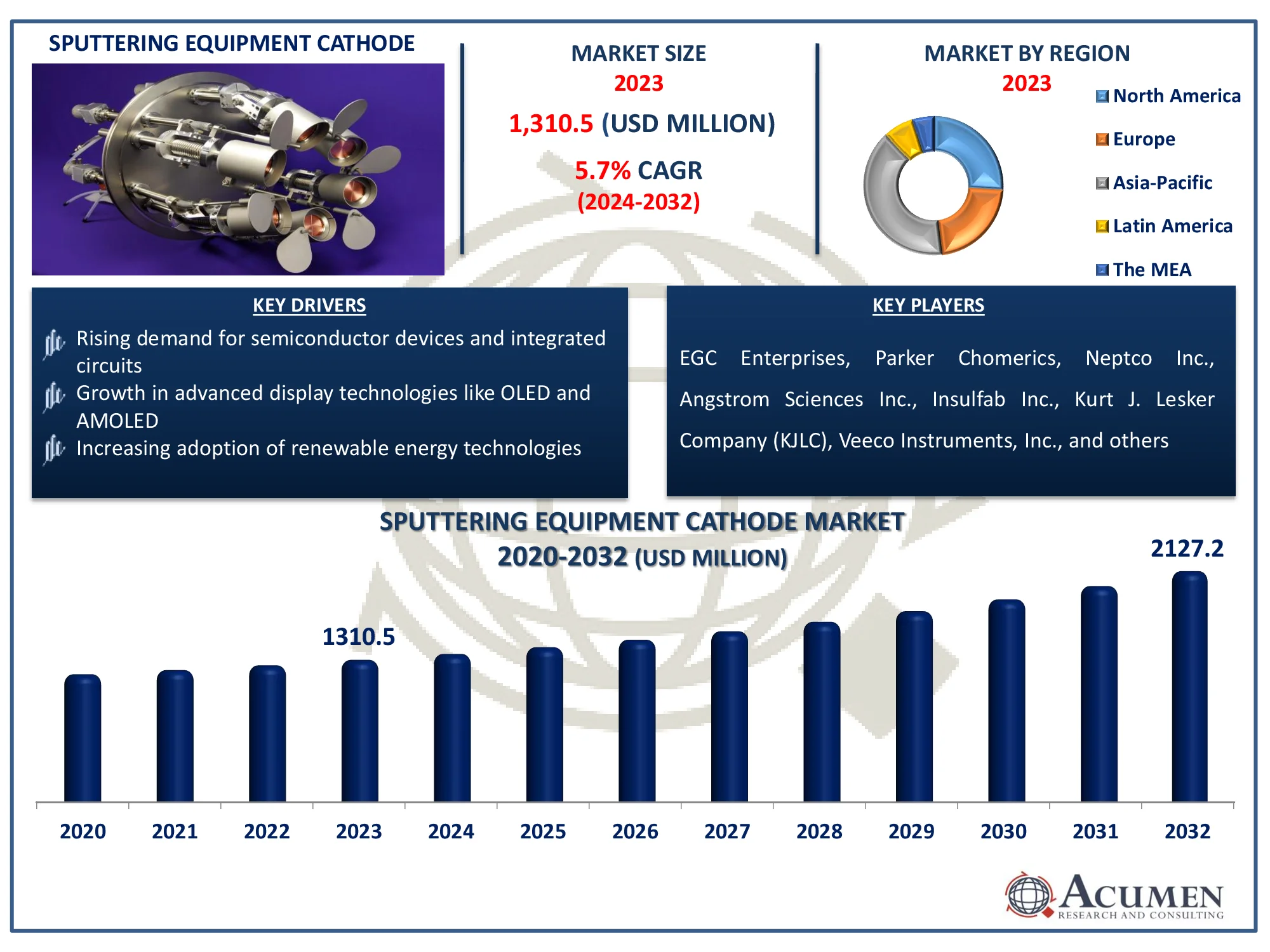

The Global Sputtering Equipment Cathode Market Size accounted for USD 1,310.5 Million in 2023 and is estimated to achieve a market size of USD 2,127.2 Million by 2032 growing at a CAGR of 5.7% from 2024 to 2032.

Sputtering Equipment Cathode Market Highlights

- Global sputtering equipment cathode market revenue is poised to garner USD 2,127.2 million by 2032 with a CAGR of 5.7% from 2024 to 2032

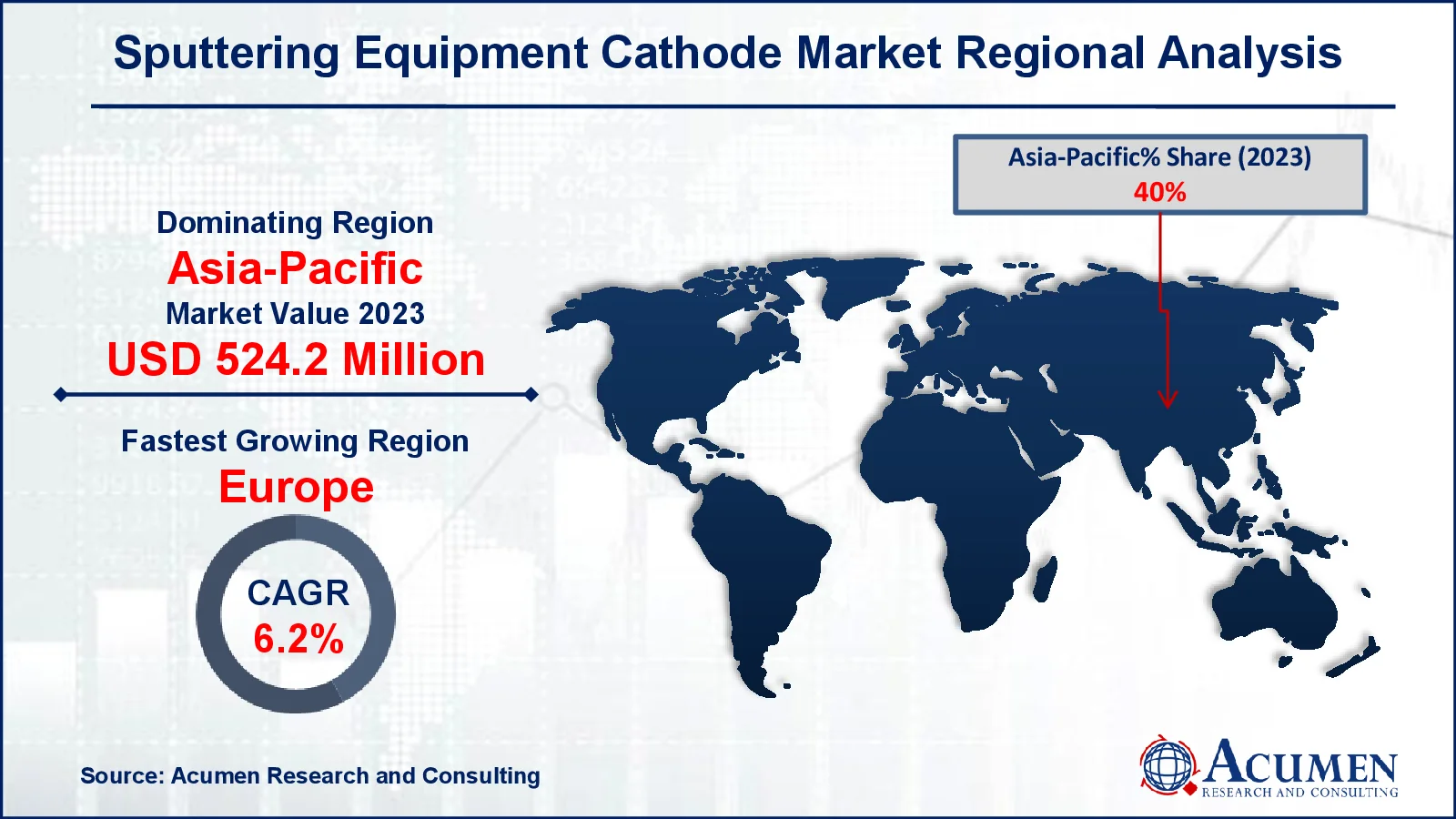

- Asia-Pacific sputtering equipment cathode market value occupied around USD 524.2 million in 2023

- Europe sputtering equipment cathode market growth will record a CAGR of more than 6.2% from 2024 to 2032

- Based on product, the circular sub-segment expected to generated 70% market share in 2023

- Sputtering equipment is in high demand for coating materials used in these industries is the sputtering equipment cathode market trend that fuels the industry demand

The growing demand for silicon wafers, driven by rising global hardware gadget demand, is expected to significantly impact market growth. Sputtering equipment is expected to see increased demand from the automobile industry as it promotes eco-friendly metallization with low VOC generation. Furthermore, it allows companies to replace expensive metal parts with lightweight and cost-effective arrangements covered in thin desired metals, hence increasing demand for cathodes.

The AIP Organization states that a key advantage of a sputtering system is its ability to easily sputter highly refractory materials, which would otherwise require complex equipment for evaporation. This capability is driving growth in the sputtering equipment cathode market as demand for efficient material processing technologies rises.

Global Sputtering Equipment Cathode Market Dynamics

Market Drivers

- Rising demand for semiconductor devices and integrated circuits

- Growth in advanced display technologies like OLED and AMOLED

- Increasing adoption of renewable energy technologies

Market Restraints

- High initial investment and operational costs

- Technical challenges in the deposition process

- Stringent environmental regulations on manufacturing processes

Market Opportunities

- Expansion of IoT and AI-based applications

- Growing investments in the development of flexible electronics

- Advances in nanotechnology and quantum computing

Sputtering Equipment Cathode Market Report Coverage

|

Market |

Sputtering Equipment Cathode Market |

|

Sputtering Equipment Cathode Market Size 2023 |

USD 1,310.5 Million |

|

Sputtering Equipment Cathode Market Forecast 2032 |

USD 2,127.2 Million |

|

Sputtering Equipment Cathode Market CAGR During 2024 - 2032 |

5.7% |

|

Sputtering Equipment Cathode Market Analysis Period |

2020 - 2032 |

|

Sputtering Equipment Cathode Market Base Year |

2023 |

|

Sputtering Equipment Cathode Market Forecast Data |

2024 - 2032 |

|

Segments Covered |

By Product, By Application, and By Geography |

|

Regional Scope |

North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

|

Key Companies Profiled |

EGC Enterprises, Parker Chomerics, Neptco Inc., Angstrom Sciences Inc., Insulfab Inc., Kurt J. Lesker Company (KJLC), Veeco Instruments, Inc., Aja International Inc., Semicore Equipment, Inc., Impact Coatings AB., Sputtering Components Inc., and Kitagawa Industries. |

|

Report Coverage |

Market Trends, Drivers, Restraints, Competitive Analysis, Player Profiling, Covid-19 Analysis, Regulation Analysis |

Sputtering Equipment Cathode Market Insights

The introduction of confocal sputtering in magnetron sputtering innovation is expected to improve the equipment's performance. Furthermore, it enables the combination of various magnetrons with varied cathode materials. These variables are used to boost the sputtering equipment's generation yield, which drives market growth.

The high demand for industry-specific knowledge and specialized expertise in the sputtering equipment cathode market leads to significant section costs, which in turn lowers the risk of new entrants. Furthermore, the disparity in proximity of limited manufacturers to locations with significant production capacity results in a highly focused business environment.

An increased number of activities by key industry participants, such as uninterrupted demands in R&D to build unique assembling forms, are expected to increase the procedure's volume throughput. Furthermore, new product development and collaborations and acquisition are expected to bolster growth in the near future. For instance, in January 2022, Kurt J. Lesker Company (KJLC) announced the significant acquisition of all assets of KDF Electronics & Vacuum Services (KDF Technologies) through an asset purchase agreement. Starting in 2022, KDF Electronics & Vacuum Services will operate under the name KDF Technologies. While KDF will remain an independent entity, it will benefit from shared services with KJLC. This, in turn, can boost the supply and demand for sputtering equipment, including cathodes, driving market growth.

To differentiate their products from competitors and gain an advantage, companies are implementing a number of innovative techniques, such as developing restricted cathode innovations and materials. Also, important players are investing in product development to decide modifications such as uniformity, homogeneity, and virtue.

Sputtering Equipment Cathode Market Segmentation

The worldwide market for sputtering equipment cathode is split based on product, application, and geography.

Sputtering Equipment Cathode Market By Product

- Linear

- Circular

The circular cathode segment dominates in sputtering equipment cathode industry, due to its uniform sputtering capability, which ensures even coating across substrates. Its design allows for efficient material utilization, reducing waste and improving cost-effectiveness. Additionally, circular cathodes are compatible with various materials and applications, making them versatile for different industrial needs. This dominance is further supported by their widespread use in semiconductor and thin-film industries.

Sputtering Equipment Cathode Market By Application

- Automotive

- Electronics

- Aerospace

- Others

According to the sputtering equipment cathode market analysis, the electronics sector is expected to show notable growth due to the high demand for precision thin-film deposition in semiconductor production. The rising production of electronic devices such as smartphones, tablets, and powerful computing systems is moving this industry ahead. Aerospace and automotive applications make significant contributions, albeit on a smaller scale, with a focus on specialized component coatings. While other industries are significant, they do not consume as much sputtering equipment as electronics do.

Sputtering Equipment Cathode Market Regional Outlook

North America

- U.S.

- Canada

Europe

- U.K.

- Germany

- France

- Spain

- Rest of Europe

Asia-Pacific

- India

- Japan

- China

- Australia

- South Korea

- Rest of Asia-Pacific

Latin America

- Brazil

- Mexico

- Rest of LATAM

The Middle East & Africa

- South Africa

- GCC Countries

- Rest of the Middle East & Africa (ME&A)

Sputtering Equipment Cathode Market Regional Analysis

For several reasons, Asia-Pacific dominates the global market, because to increased semiconductor production in China, India, South Korea, and Taiwan. For instance, 'SemiconIndia 2023' is being organized by the India Semiconductor Mission in collaboration with industry leaders and associations, under the visionary guidance of Hon'ble Prime Minister Shri Narendra Modi. The event aims to establish India as a global hub for semiconductor design, manufacturing, and technology development. Furthermore, the popularity of PVD coatings from solar PV and restorative equipment generation ventures is expected to have a significant impact on growth in the near future.

China is expected to demonstrate the most impressive car production over the projected time frame, which is expected to benefit the market because the company uses numerous parts covered with sputtering equipment. Furthermore, in order to have a significant impact on the territorial market in the coming years, development of hybrid/electric and green vehicles is undertaken.

Europe is expected to experience a surge in demand over the forecast period as a result of the growing interest in PVD coatings across various categories, such as medical equipment and protective devices. Furthermore, it is replacing traditional covering strategies as a result of the European Commission's chromium ban, hence increasing market growth.

Sputtering Equipment Cathode Market Players

Some of the top sputtering equipment cathode companies offered in our report includes EGC Enterprises, Parker Chomerics, Neptco Inc., Angstrom Sciences Inc., Insulfab Inc., Kurt J. Lesker Company (KJLC), Veeco Instruments, Inc., Aja International Inc., Semicore Equipment, Inc., Impact Coatings AB., Sputtering Components Inc., and Kitagawa Industries.

Frequently Asked Questions

How big is the sputtering equipment cathode market?

The sputtering equipment cathode market size was valued at USD 1,310.5 million in 2023.

What is the CAGR of the global sputtering equipment cathode market from 2024 to 2032?

The CAGR of sputtering equipment cathode is 5.7% during the analysis period of 2024 to 2032.

Which are the key players in the sputtering equipment cathode market?

The key players operating in the global market are including EGC Enterprises, Parker Chomerics, Neptco Inc., Angstrom Sciences Inc., Insulfab Inc., Kurt J. Lesker Company (KJLC), Veeco Instruments, Inc., Aja International Inc., Semicore Equipment, Inc., Impact Coatings AB., Sputtering Components Inc., and Kitagawa Industries.

Which region dominated the global sputtering equipment cathode market share?

Asia-Pacific held the dominating position in sputtering equipment cathode industry during the analysis period of 2024 to 2032.

Which region registered fastest CAGR from 2024 to 2032?

Europe region exhibited fastest growing CAGR for market of sputtering equipment cathode during the analysis period of 2024 to 2032.

What are the current trends and dynamics in the global sputtering equipment cathode industry?

The current trends and dynamics in the sputtering equipment cathode industry include rising demand for semiconductor devices and integrated circuits, growth in advanced display technologies like OLED and AMOLED, and increasing adoption of renewable energy technologies

Which Product held the maximum share in 2023?

The circular expected to held the maximum share of the sputtering equipment cathode industry.?