Machine Vision Market Size - Global Industry, Share, Analysis, Trends and Forecast 2023 - 2032

Published :

Report ID:

Pages :

Format :

Machine Vision Market Size - Global Industry, Share, Analysis, Trends and Forecast 2023 - 2032

Report Coverage

- Industry Dynamics

- Market Size and Forecast Data

- Segment Analysis

- Competitive Landscape

- Regional Analysis with a Niche Focus on Country-Level Data

- High Level Analysis - Porter's, PESTEL, Value Chain, etc.

- Company Profiles of Key Players

- Option to Customize the Report As Per Your Specific Need

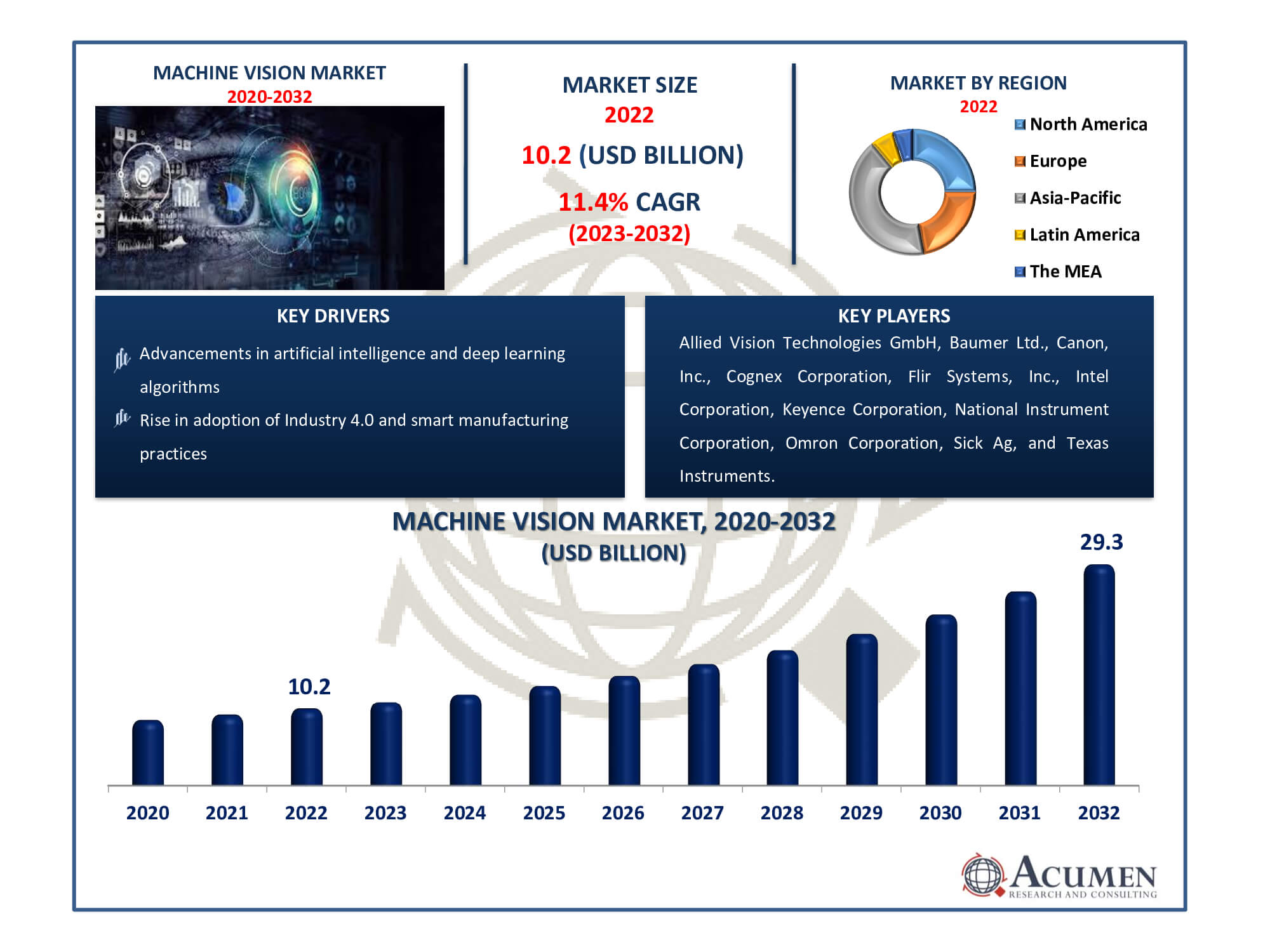

Request Sample Report

The Global Machine Vision Market Size accounted for USD 10.2 Billion in 2022 and is estimated to achieve a market size of USD 29.3 Billion by 2032 growing at a CAGR of 11.4% from 2023 to 2032.

Machine Vision Market Highlights

- Global machine vision market revenue is poised to garner USD 29.3 billion by 2032 with a CAGR of 11.4% from 2023 to 2032

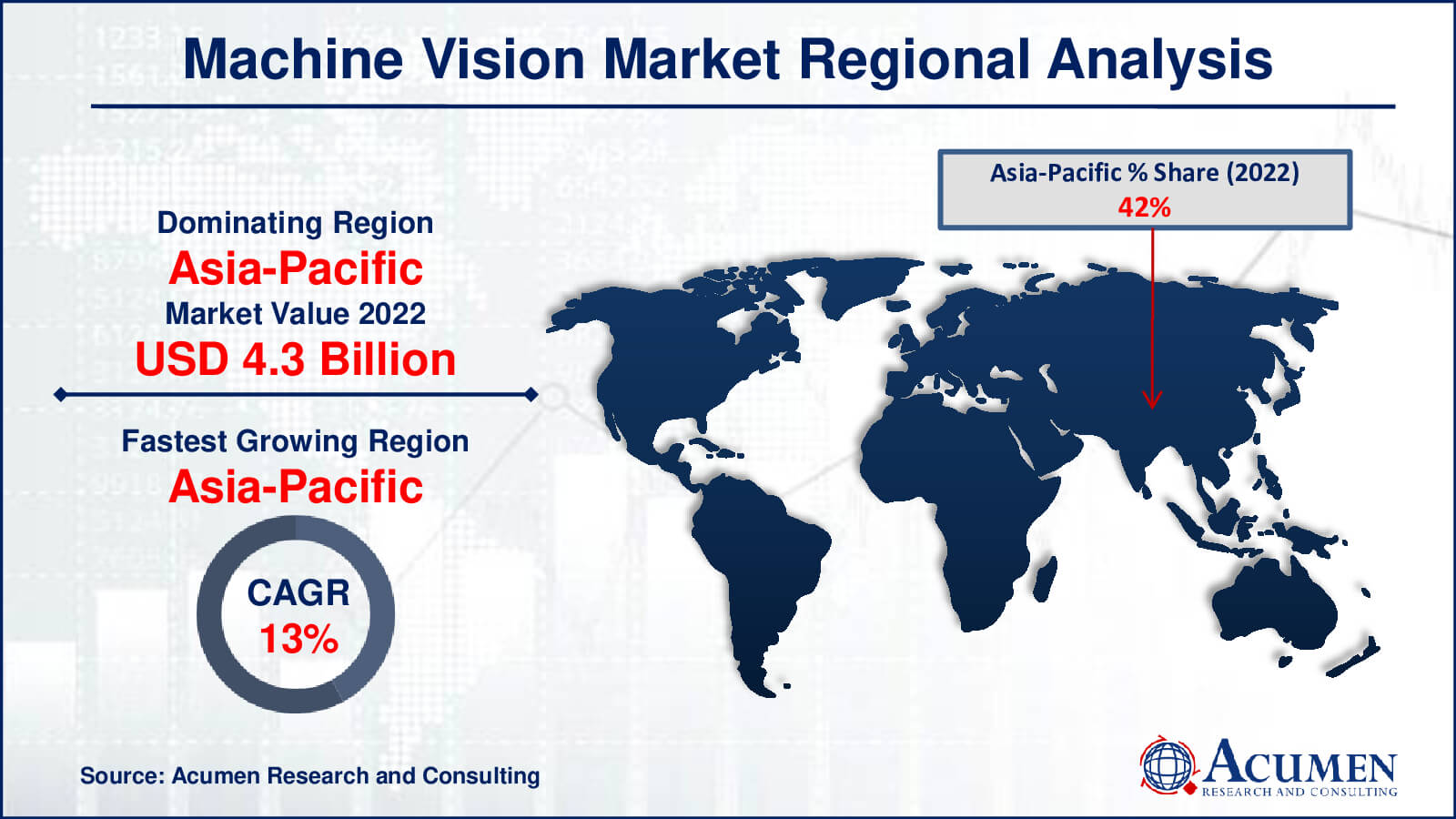

- Asia-Pacific machine vision market value occupied around USD 4.3 billion in 2022

- Asia-Pacific machine vision market growth will record a CAGR of more than 13% from 2023 to 2032

- Among offering, the hardware sub-segment generated over US$ 6.3 billion revenue in 2022

- Based on product, the PC based sub-segment generated around 55% share in 2022

- Increased demand for 3D vision systems in various industries for precise measurements and analysis is a popular machine vision market trend that fuels the industry demand

Machine vision is the technology that allows machines to comprehend and interpret their surroundings by using visual input. It allows computers to analyze, comprehend, and make judgments using images or video. This technology combines cameras and computer algorithms to accomplish activities such as item detection, inspection, measurement, and quality control in a variety of industries including manufacturing, healthcare, agriculture, and others. The machine vision industry is quickly expanding as a result of its numerous uses in automation and quality assurance. It is predicted to grow further as industry seek more effective ways to improve processes, boost production, and maintain high-quality standards through automated visual inspection systems and analysis tools. This market expansion is being driven by breakthroughs in hardware, software, and artificial intelligence, making machine vision an essential component of modern technological advancements.

Global Machine Vision Market Dynamics

Market Drivers

- Increasing demand for automation across industries

- Advancements in artificial intelligence and deep learning algorithms

- Growing need for quality inspection and defect detection

- Rise in adoption of Industry 4.0 and smart manufacturing practices

Market Restraints

- High initial setup costs for implementing machine vision systems

- Challenges in integrating diverse technologies and systems

- Concerns regarding data privacy and security in vision-based systems

Market Opportunities

- Expansion in healthcare applications for diagnostics and treatment

- Integration of machine vision with IoT for enhanced data analysis

- Emergence of edge computing for real-time image processing

Machine Vision Market Report Coverage

| Market | Machine Vision Market |

| Machine Vision Market Size 2022 | USD 10.2 Billion |

| Machine Vision Market Forecast 2032 | USD 29.3 Billion |

| Machine Vision Market CAGR During 2023 - 2032 | 11.4% |

| Machine Vision Market Analysis Period | 2020 - 2032 |

| Machine Vision Market Base Year |

2022 |

| Machine Vision Market Forecast Data | 2023 - 2032 |

| Segments Covered | By Offering, By Product, By Application, By End-User, And By Geography |

| Regional Scope | North America, Europe, Asia Pacific, Latin America, and Middle East & Africa |

| Key Companies Profiled | Allied Vision Technologies GmbH, Baumer Ltd., Canon, Inc., Cognex Corporation, Flir Systems, Inc., Intel Corporation, Keyence Corporation, National Instrument Corporation, Omron Corporation, Sick Ag, Texas Instruments, and Microscan Systems, Inc. |

| Report Coverage |

Market Trends, Drivers, Restraints, Competitive Analysis, Player Profiling, Covid-19 Analysis, Regulation Analysis |

Machine Vision Market Insights

Machine vision is used in industries all around the world to make work easier and faster. Consider intelligent machines to have eyes they can see and understand things just like us! This enables industries and businesses to do tasks swiftly and accurately. They utilize this technology to evaluate products, sort things out, and even guide machines to accomplish their work without the need for human intervention. Automation is equivalent to having super helpers who never tire or make mistakes. Industries love it because it saves them time and money while ensuring the quality of their products.

Starting with machine vision might be compared to purchasing a high end car it is expensive at first. Companies must purchase the appropriate equipment, configure the systems, and train their employees on how to utilize it. All of this might leave a significant dent in their wallets. It's like a barrier they must clear before they can reap the advantages. Because it is so expensive at first, businesses may worry if it is worthwhile in the long run. Because of the high initial cost, industries are sometimes hesitant to use machine vision technology.

Imagine giving machines super-smart eyes and linking them to the internet that is what occurs when we combine machine vision and the Internet of Things (IoT). This combination opens up a world of possibilities. It's like teaching machines to not only see, but also talk and share data. Consider this: machines in a factory communicating with one another, predicting when they will need repairs even before something goes wrong. They become extremely efficient, allowing industries to run smoothly. This combination opens up a slew of possibilities for making processes smarter, decreasing errors, and enhancing how things are done. It's like handing industry a hidden weapon for increasing efficiency and staying ahead of the competition.

Machine Vision Market Segmentation

The worldwide market for machine vision is split based on offering, product, application, end-user, and geography.

Machine Vision Offerings

- Hardware

- Frame Grabber

- Camera

- Processor

- LED Lighting

- Optics/Lenses

- Software

- Standard Algorithm

- Deep Learning Software

- Barcode Reading

- Services

- Solution Management

- Integration

According to machine vision industry analysis, hardware have held the largest portion in the past years within the offering segment, because of its basic role in gathering, processing, and interpreting visual data. High-resolution cameras, advanced sensors, and powerful processors serve as the backbone of machine vision systems, allowing for exact image capture and real-time analysis. The hardware segment is at the forefront due to its critical role in assuring accuracy, speed, and adaptability to varied applications. As technology advances, hardware advancements continue to drive market expansion by catering to changing industry needs in the industrial, healthcare, automotive, and robotics sectors.

Machine Vision Products

- Smart Camera Based

- PC Based

The PC-based segment leads the machine vision business because to its versatility and substantial processing capabilities. PC-based systems use computers computing capacity to handle sophisticated algorithms and large amounts of data, providing customization and scalability. These systems may support a wide range of software applications as well as increasing technology advances. PC-based machine vision systems serve a wide range of industries due to their ability to integrate smoothly into existing infrastructures and provide extensive connectivity choices. Their versatility, processing power, and compatibility with diverse software make them the favoured choice for applications requiring extensive image analysis and algorithmic complexities.

Machine Vision Applications

- Positioning and Guidance

- Quality Assurance and Inspection

- Identification

- Measurement

The machine vision market's, quality assurance and inspection, commands its largest section. It is the key to ensuring that products satisfy high standards, assuring faultless quality and precision across sectors. This category ensures manufacturing excellence with machine vision's keen eye and consistent accuracy. It is the protector of perfection, avoiding flaws and assuring conformity by scrutinising minute details and detecting imperfections at extraordinary speeds. As industries prioritise high-quality manufacturing, the need for machine vision systems for inspection and quality assurance rises, cementing this segment's vital role as the foundation of flawless production and consumer pleasure.

Machine Vision End-Users

- Pharmaceuticals & Chemicals

- Automotive

- Pulp & Paper

- Electronics & Semiconductor

- Food & Beverage

- Printing & Labeling

- Postal & Logistics

- Glass & Metal

- Other

According to the machine vision market forecast, the automotive segments have dominated the market share and are likely to continue its dominance throughout the forecasted timeframe from 2023 to 2032. Machine vision plays a critical part in revolutionising automobile manufacturing, with an unwavering focus on safety, efficiency, and cutting-edge technology. It's the imaginative eye behind immaculate quality control, detailed part inspection, and faultless guiding systems, from assuring flawlessness in assembly lines to enabling autonomous vehicle developments. As the automotive industry accelerates towards a future of electric and self-driving vehicles, machine vision will serve as an important guide, stimulating innovation and altering the fundamental definition of mobility.

Machine Vision Market Regional Outlook

North America

- U.S.

- Canada

Europe

- U.K.

- Germany

- France

- Spain

- Rest of Europe

Asia-Pacific

- India

- Japan

- China

- Australia

- South Korea

- Rest of Asia-Pacific

Latin America

- Brazil

- Mexico

- Rest of Latin America

The Middle East & Africa

- South Africa

- GCC Countries

- Rest of the Middle East & Africa (ME&A)

Machine Vision Market Regional Analysis

Asia-Pacific's supremacy is due to rising industrialization, particularly in countries such as China, Japan, South Korea, and India. Machine vision is being used in industries such as automotive, electronics, and manufacturing to improve quality control, production efficiency, and automation. Consumer electronics growth, automotive developments, and expanded manufacturing activity all contribute considerably to the region's market share. Furthermore, favorable government measures that boost industrial automation and technology breakthroughs drive the market's exponential expansion.

North America is close behind in terms of machine vision usage, thanks to the advanced technological landscape and the existence of businesses such as automotive, electronics, and pharmaceuticals. The region's concentration on innovation, particularly in robotics and driverless cars, drives demand for machine vision systems. Furthermore, the growing demand for quality assurance, inspection, and technical developments in various industrial processes leads to its large market share.

Despite its smaller market size, Europe remains an important player in the machine vision environment. The region has a significant industrial base, especially in the automotive and electronics industries, where machine vision is essential for quality control and production optimization. However, due to variables like as economic instability and varying adoption rates across industries, market growth in Europe is slightly slower than in Asia-Pacific and North America.

Machine Vision Market Players

Some of the top machine vision companies offered in our report includes Allied Vision Technologies GmbH, Baumer Ltd., Canon, Inc., Cognex Corporation, Flir Systems, Inc., Intel Corporation, Keyence Corporation, National Instrument Corporation, Omron Corporation, Sick Ag, Texas Instruments, and Microscan Systems, Inc.

Frequently Asked Questions

How big is the machine vision market?

The market size of machine vision was USD 10.2 Billion in 2022.

What is the CAGR of the global machine vision market from 2023 to 2032?

The CAGR of machine vision is 11.4% during the analysis period of 2023 to 2032.

Which are the key players in the machine vision market?

The key players operating in the global market are including Allied Vision Technologies GmbH, Baumer Ltd., Canon, Inc., Cognex Corporation, Flir Systems, Inc., Intel Corporation, Keyence Corporation, National Instrument Corporation, Omron Corporation, Sick Ag, Texas Instruments, and Microscan Systems, Inc.

Which region dominated the global machine vision market share?

Asia-Pacific held the dominating position in machine vision industry during the analysis period of 2023 to 2032.

Which region registered fastest CAGR from 2023 to 2032?

Asia-Pacific region exhibited fastest growing CAGR for market of machine vision during the analysis period of 2023 to 2032.

What are the current trends and dynamics in the global machine vision industry?

The current trends and dynamics in the machine vision industry include increasing demand for automation across industries, advancements in artificial intelligence and deep learning algorithms, growing need for quality inspection and defect detection, and rise in adoption of industry 4.0 and smart manufacturing practices.

Which offering held the maximum share in 2022?

The hardware offering held the maximum share of the machine vision industry.