Screen-Printing Inks Market Size - Global Industry, Share, Analysis, Trends and Forecast 2024 - 2032

Published :

Report ID:

Pages :

Format :

Screen-Printing Inks Market Size - Global Industry, Share, Analysis, Trends and Forecast 2024 - 2032

Report Coverage

- Industry Dynamics

- Market Size and Forecast Data

- Segment Analysis

- Competitive Landscape

- Regional Analysis with a Niche Focus on Country-Level Data

- High Level Analysis - Porter's, PESTEL, Value Chain, etc.

- Company Profiles of Key Players

- Option to Customize the Report As Per Your Specific Need

Request Sample Report

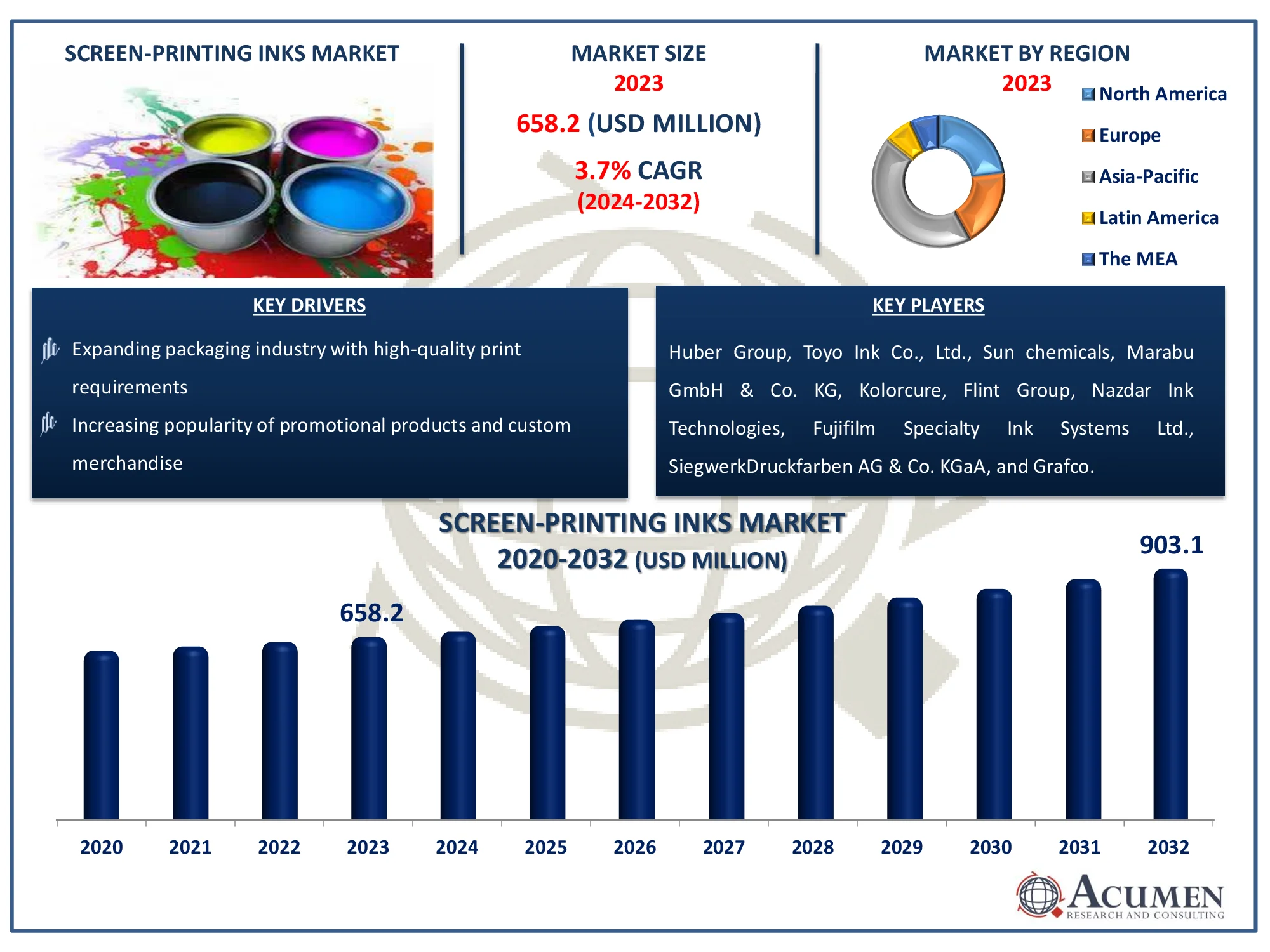

The Global Screen-Printing Inks Market Size accounted for USD 658.2 Million in 2023 and is estimated to achieve a market size of USD 903.1 Million by 2032 growing at a CAGR of 3.7% from 2024 to 2032

Screen-Printing Inks Market (By Type: Water-based, Solvent-based, UV-cured, and Others; By End Use Material: Plastics, Ceramics, Paper, Fabrics, and Glass; By Application: Commercial Printing, Publication, Labels & Packaging, and Others; and By Region: North America, Europe, Asia-Pacific, Latin America, and MEA)

Screen-Printing Inks Market Highlights

- Global screen printing inks market revenue is poised to garner USD 903.1 million by 2032 with a CAGR of 3.7% from 2024 to 2032

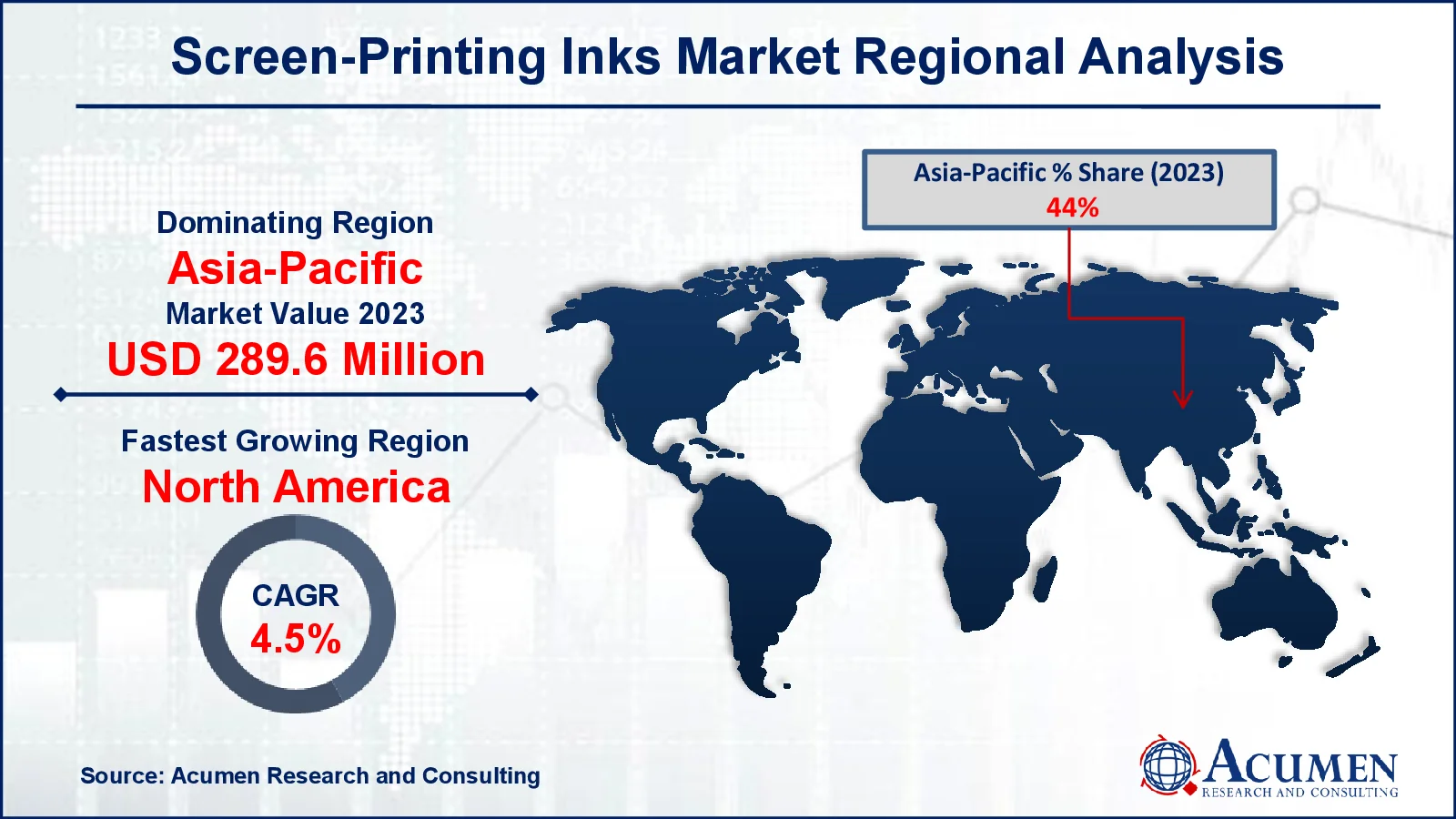

- Asia-Pacific screen printing inks market value occupied around USD 289.6 million in 2023

- North America screen printing inks market growth will record a CAGR of more than 4.5% from 2024 to 2032

- Among end use material, the plastics sub-segment generated notable revenue in 2023

- Based on application, the labels & packaging sub-segment generated significant market screen printing inks share in 2023

- Growth in emerging markets with rising demand for custom printed goods is a popular screen printing inks market trend that fuels the industry demand

Screen-printing inks are specialized formulations used in the screen-printing process to transfer designs onto various surfaces, such as textiles, paper, ceramics, and plastics. These inks pass through a mesh screen onto the substrate, leaving a precise, vibrant image or pattern. Screen-printing inks are available in several types, including solvent-based, water-based, plastisol, and UV-cured, each offering different properties for various applications. Solvent-based inks are known for their durability, while water-based options are more eco-friendly. Plastisol inks are commonly used in fabric printing due to their opacity and flexibility. UV-cured inks are gaining popularity for their fast drying time and durability. Screen-printing inks are widely used in industries like textiles, packaging, advertising, and electronics.

Global Screen-Printing Inks Market Dynamics

Market Drivers

- Growing demand for printed textiles in fashion and home décor

- Expanding packaging industry with high-quality print requirements

- Increasing popularity of promotional products and custom merchandise

- Rising adoption of UV-cured screen-printing inks for faster production

Market Restraints

- High environmental impact and regulatory restrictions on solvent-based inks

- Availability of digital printing as an efficient alternative

- Volatility in raw material prices impacting production costs

Market Opportunities

- Development of eco-friendly, water-based screen-printing inks

- Technological advancements in ink formulation for enhanced durability

- Expanding applications in electronics and printed circuits

Screen-Printing Inks Market Report Coverage

| Market | Screen-Printing Inks Market |

| Screen-Printing Inks Market Size 2022 |

USD 658.2 Million |

| Screen-Printing Inks Market Forecast 2032 | USD 903.1 Million |

| Screen-Printing Inks Market CAGR During 2023 - 2032 | 3.7% |

| Screen-Printing Inks Market Analysis Period | 2020 - 2032 |

| Screen-Printing Inks Market Base Year |

2023 |

| Screen-Printing Inks Market Forecast Data | 2024 - 2032 |

| Segments Covered | By Type, By End Use Material, By Application, And By Geography |

| Regional Scope | North America, Europe, Asia Pacific, Latin America, and Middle East & Africa |

| Key Companies Profiled | Huber Group, Toyo Ink Co., Ltd., Sun Chemicals, Marabu GmbH & Co. KG, Kolorcure, Flint Group, Nazdar Ink Technologies, Fujifilm Specialty Ink Systems Ltd., SiegwerkDruckfarben AG & Co. KGaA, and Grafco etc. |

| Report Coverage |

Market Trends, Drivers, Restraints, Competitive Analysis, Player Profiling, Covid-19 Analysis, Regulation Analysis |

Screen-Printing Inks Market Insights

Improvement in screen printing technology is one of the driving forces that increase the demand for screen printing inks. Also, the increase in the number of stringent government regulations related to the printing colors that have an adverse effect on the health across the globe is encouraging the use of screen printing inks across end-use industries which can be one of the key factors boosting the growth of the global screen printing inks market.

The rise in technological advancements have transformed the inks industry as the printing presses are making efficient use of automated equipment which is faster as compared to traditional printing. Also, the environment-friendly inks that include vegetable oil-based inks and water-based inks are in huge demand as there is growing concerns related to environmental pollution. UV-cured inks are expected to hold the largest share in the global market. Benefits of screen printing inks over other methods will have a positive influence on the overall screen printing inks market. Also, the advancement in digital ink technology is rapidly gaining popularity and is expected to create profitable opportunities for key manufacturers in the global screen printing inks market forecast period.

Screen-Printing Inks Market Segmentation

The worldwide market for screen printing inks is split based on type, end use material, application, and geography.

Screen Printing Inks Market By Types

- Water-based

- Solvent-based

- UV-cured

- Others

According to screen-printing inks industry analysis, water-based inks dominate the market. Their eco-friendly nature, coupled with the rising awareness of sustainable printing practices, has led to increased demand. Water-based inks are known for their versatility, allowing for easy application on a wide range of substrates, particularly fabrics and textiles. They are also considered less harmful to the environment due to lower volatile organic compound (VOC) emissions, making them a preferred choice in industries focusing on environmental sustainability.

Screen Printing Inks Market By End Use Materials

- Plastics

- Ceramics

- Paper

- Fabrics

- Glass

When it comes to end-use materials, plastics stand out as the notable segment in the screen printing inks market. The widespread use of screen-printing on various plastic surfaces, particularly in packaging and labeling, has driven this material's dominance. With plastics being a staple material in industries ranging from food and beverage to cosmetics and consumer goods, the demand for durable, high-quality screen-printing inks tailored for plastic substrates remains high. Plastics provide a smooth, non-porous surface that holds inks well, making them ideal for high-visibility printing applications.

Screen Printing Inks Market By Applications

- Commercial Printing

- Publication

- Labels & Packaging

- Others

Within the application segment, labels & packaging takes the lead. As global packaging needs grow, particularly with the rise in e-commerce and product branding, the demand for screen-printing inks in this sector has surged. High-quality labeling and packaging are essential for brand recognition and compliance with industry standards, particularly in fast-moving consumer goods (FMCG). Screen-printing provides a cost-effective solution for creating detailed and long-lasting prints on packaging materials, further cementing its importance in this application.

Screen-Printing Inks Market Regional Outlook

North America

- U.S.

- Canada

Europe

- U.K.

- Germany

- France

- Spain

- Rest of Europe

Asia-Pacific

- India

- Japan

- China

- Australia

- South Korea

- Rest of Asia-Pacific

Latin America

- Brazil

- Mexico

- Rest of Latin America

The Middle East & Africa

- South Africa

- GCC Countries

- Rest of the Middle East & Africa (ME&A)

Screen-Printing Inks Market Regional Analysis

The Asia-Pacific region is expected to dominate the global screen printing inks market owing to the rising demand from end-use industries such as automotive, packaging and textile industry from emerging countries such as India, Malaysia, and other countries. The presence of improved and highly automated printing equipment and the increasing demand for screen printing inks in commercial painting and extensive usage of screen printing inks in automotive, packaging and advertising industry are some of the major factors driving the growth of the screen printing inks market. Also, the North America region is expected to grow at a moderate pace owing to the rise in consumption of UV-cured inks in advertising and textile printing applications. These factors expected to drive the screen printing inks market in the North America region.

Screen-Printing Inks Market Players

Some of the top screen-printing inks companies offered in our report includes Huber Group, Toyo Ink Co., Ltd., Sun Chemicals, Marabu GmbH & Co. KG, Kolorcure, Flint Group, Nazdar Ink Technologies, Fujifilm Specialty Ink Systems Ltd., Siegwerk Druckfarben AG & Co. KGaA, and Grafco.

Frequently Asked Questions

How big is the screen-printing inks market?

The screen-printing Inks market size was valued at USD 658.2 million in 2023.

What is the CAGR of the global screen-printing inks market from 2024 to 2032?

The CAGR of screen-printing inks is 3.7% during the analysis period of 2024 to 2032.

Which are the key players in the screen-printing Inks market?

The key players operating in the global market are including Huber Group, Toyo Ink Co., Ltd., Sun Chemicals, Marabu GmbH & Co. KG, Kolorcure, Flint Group, Nazdar Ink Technologies, Fujifilm Specialty Ink Systems Ltd., SiegwerkDruckfarben AG & Co. KGaA, and Grafco.

Which region dominated the global screen-printing inks market share?

Asia-Pacific North America held the dominating position in screen-printing inks industry during the analysis period of 2024 to 2032.

Which region registered fastest CAGR from 2024 to 2032?

North America region exhibited fastest growing CAGR for market of screen-printing inks during the analysis period of 2024 to 2032.

What are the current trends and dynamics in the global screen-printing inks industry?

The current trends and dynamics in the screen-printing inks industry include growing demand for printed textiles in fashion and home d�cor, expanding packaging industry with high-quality print requirements, increasing popularity of promotional products and custom merchandise, and rising adoption of UV-cured screen-printing inks for faster production.

Which end use material held the maximum share in 2023?

The labels & packaging end use material held the notable share of the screen-printing inks industry.