PET Preform Machines Market Size - Global Industry, Share, Analysis, Trends and Forecast 2023 - 2032

Published :

Report ID:

Pages :

Format :

PET Preform Machines Market Size - Global Industry, Share, Analysis, Trends and Forecast 2023 - 2032

Report Coverage

- Industry Dynamics

- Market Size and Forecast Data

- Segment Analysis

- Competitive Landscape

- Regional Analysis with a Niche Focus on Country-Level Data

- High Level Analysis - Porter's, PESTEL, Value Chain, etc.

- Company Profiles of Key Players

- Option to Customize the Report As Per Your Specific Need

Request Sample Report

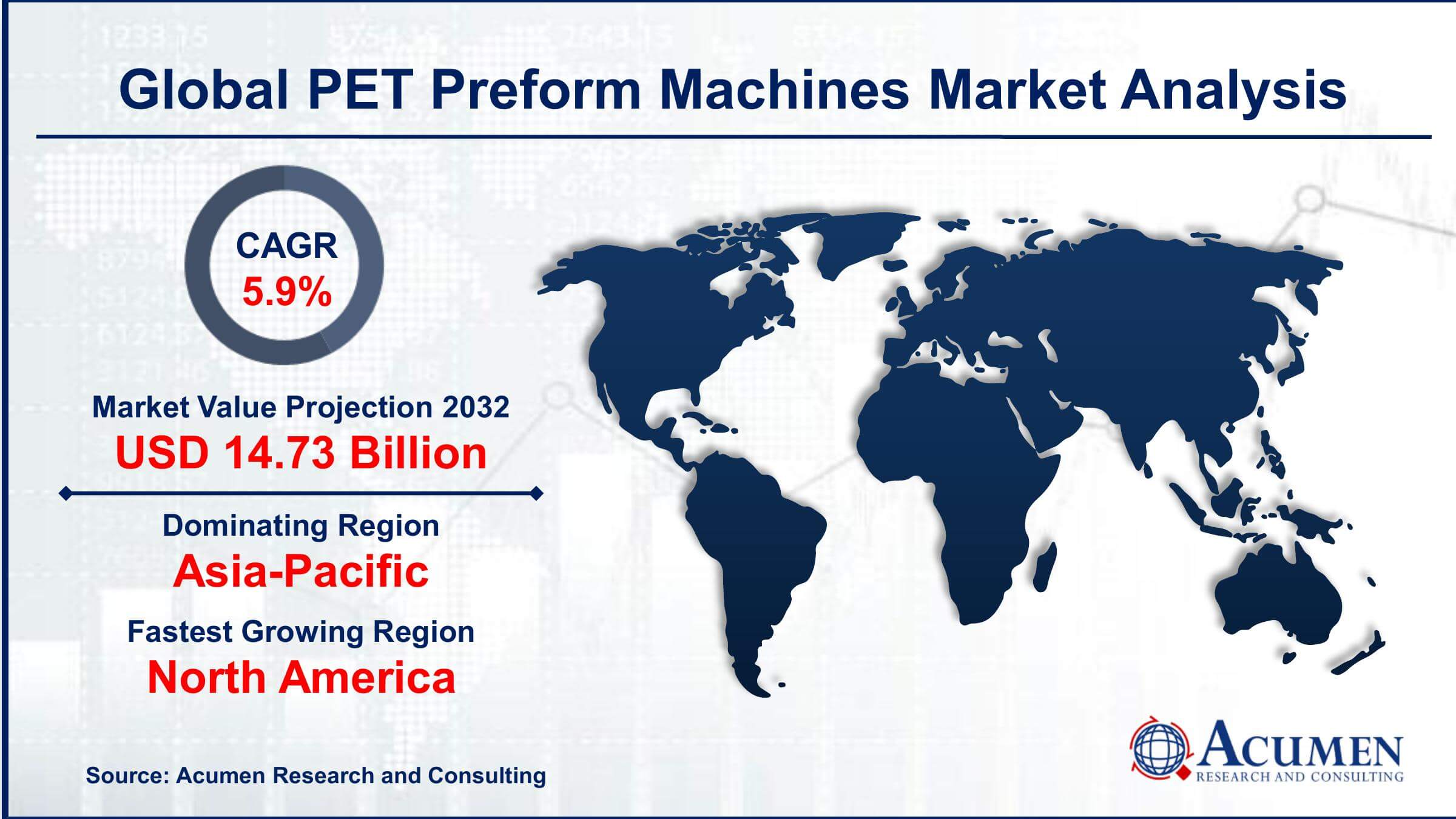

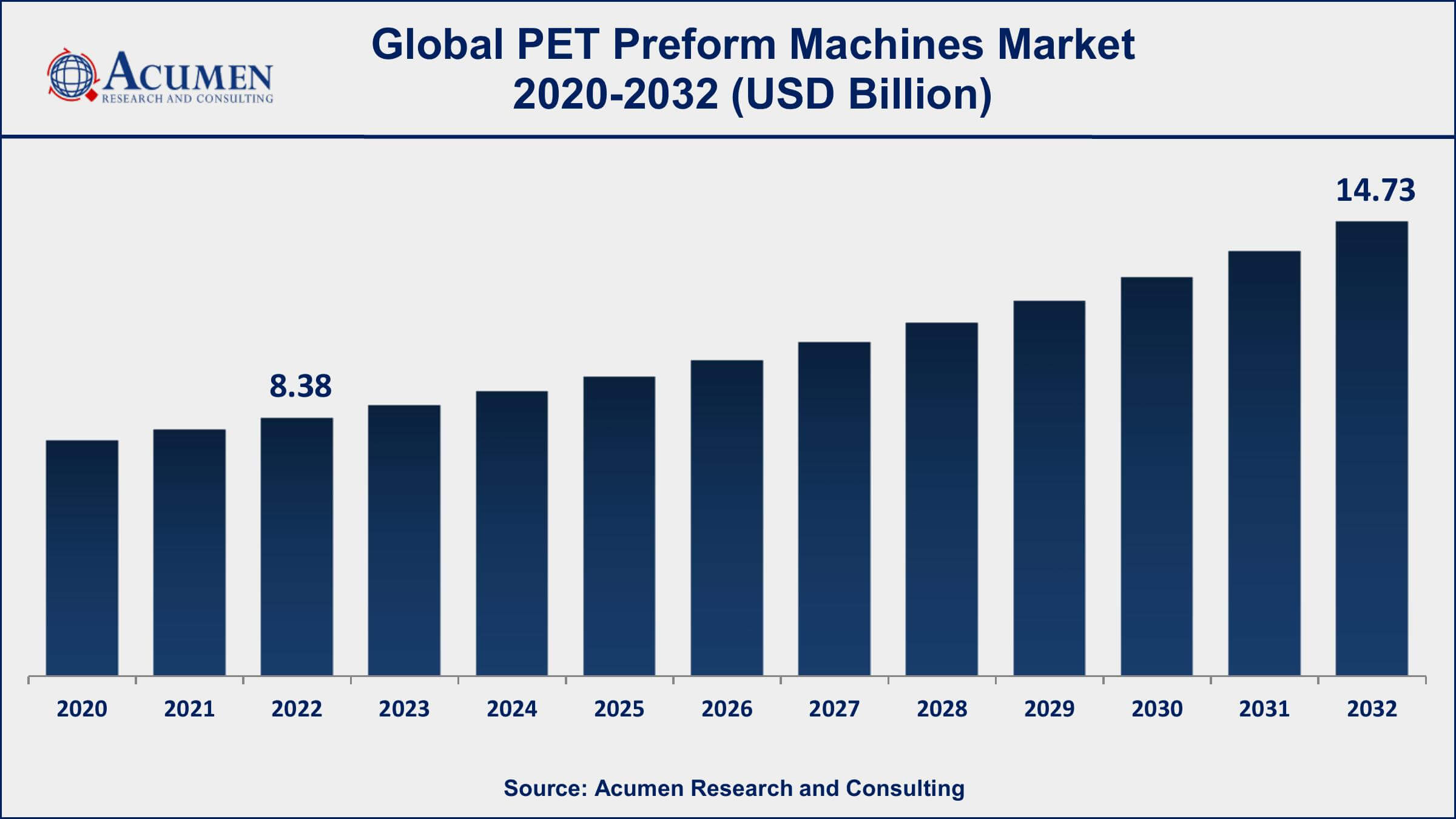

The Global PET Preform Machines Market Size accounted for USD 8.38 Billion in 2022 and is projected to achieve a market size of USD 14.73 Billion by 2032 growing at a CAGR of 5.9% from 2023 to 2032.

PET Preform Machines Market Highlights

- Global PET Preform Machines Market revenue is expected to increase by USD 14.73 Billion by 2032, with a 5.9% CAGR from 2023 to 2032

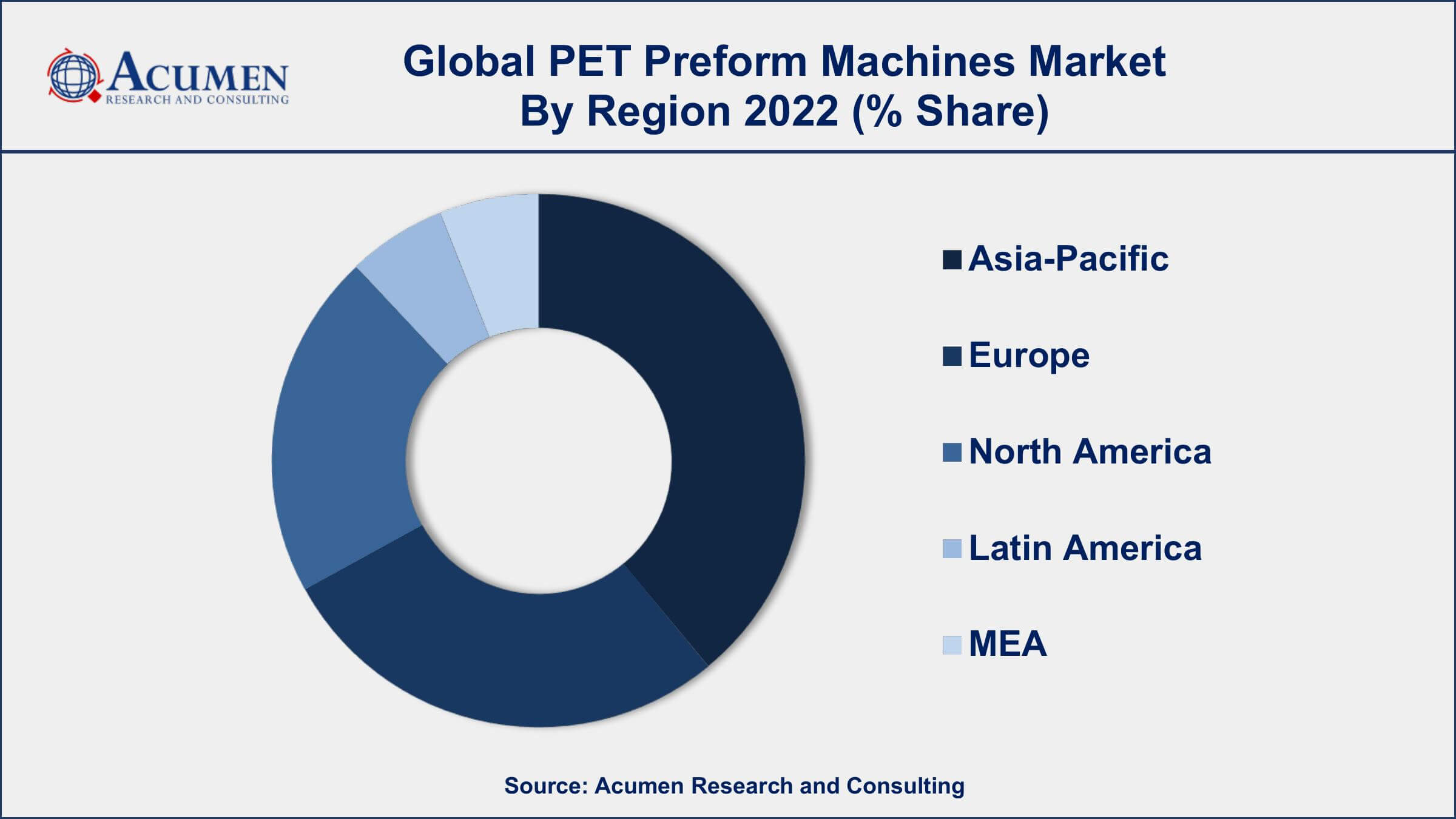

- Asia-Pacific region led with more than 36% of PET Preform Machines Market share in 2022

- North America PET Preform Machines Market growth will record a CAGR of around 6.3% from 2023 to 2032

- By technology, the injection molding segment has recorded more than 61% of the revenue share in 2022.

- By application, the carbonated beverages segment is predicted to grow at the fastest CAGR of 6.4% between 2023 and 2032

- Growing demand for PET bottles in the food and beverage industry, drives the PET Preform Machines Market value

PET preform machines are specialized manufacturing equipment used to produce PET (polyethylene terephthalate) preforms, which are intermediate products used in the production of PET bottles and containers through a process called stretch blow molding. These preforms are typically cylindrical or tubular in shape and serve as the starting point for creating a wide range of plastic bottles used for beverages, food, personal care products, and more. PET preform machines are designed to efficiently and precisely mold molten PET material into preform shapes, which are then cooled and stored before being transported to the blow molding process.

The market for PET preform machines has witnessed significant growth over the years, driven by the expanding demand for PET bottles and containers across various industries. The growth of the packaged food and beverage industry, as well as increasing consumer preference for lightweight, recyclable, and transparent packaging, has contributed to the rising demand for PET bottles. This, in turn, has fueled the demand for PET preform machines, as they play a crucial role in ensuring the efficient and cost-effective production of high-quality PET preforms. Additionally, technological advancements in PET preform machine design have led to improved automation, energy efficiency, and production speeds, further boosting the adoption of these machines by manufacturers.

Global PET Preform Machines Market Trends

Market Drivers

- Growing demand for PET bottles in the food and beverage industry

- Increasing preference for lightweight and transparent packaging solutions

- Technological advancements enhancing machine automation and efficiency

- Urbanization and changing consumer lifestyles driving packaged goods consumption

- The rise of e-commerce and online grocery shopping boosting packaging needs

Market Restraints

- Fluctuations in raw material prices affecting production costs

- Environmental concerns and regulations impacting plastic packaging usage

Market Opportunities

- Expansion of PET packaging into pharmaceuticals and personal care sectors

- Strong emphasis on sustainable and recyclable packaging solutions

PET Preform Machines Market Report Coverage

| Market | PET Preform Machines Market |

| PET Preform Machines Market Size 2022 | USD 8.38 Billion |

| PET Preform Machines Market Forecast 2032 | USD 14.73 Billion |

| PET Preform Machines Market CAGR During 2023 - 2032 | 5.9% |

| PET Preform Machines Market Analysis Period | 2020 - 2032 |

| PET Preform Machines Market Base Year | 2022 |

| PET Preform Machines Market Forecast Data | 2023 - 2032 |

| Segments Covered | By Technology, By Number of Cavities, By Application, By End-use, And By Geography |

| Regional Scope | North America, Europe, Asia Pacific, Latin America, and Middle East & Africa |

| Key Companies Profiled | Husky Injection Molding Systems, SIPA S.p.A., Nissei ASB Machine Co., Ltd., Sacmi Group, Netstal-Machinery Ltd., Krones AG, KraussMaffei Group, Sidel Group, Chumpower Machinery Corp., Powerjet Plastic Machinery Co., Ltd., Demark Holding Group, and Jon Wai Machinery Works Co., Ltd. |

| Report Coverage |

Market Trends, Drivers, Restraints, Competitive Analysis, Player Profiling, Covid-19 Analysis, Regulation Analysis |

PET is a widely used plastic material known for its clarity, strength, lightweight nature, and recyclability. The preform manufacturing process involves melting PET resin pellets and then injecting the molten material into a preform mold to create a tube-like shape with a threaded neck. These preforms are then cooled, solidified, and stored before they are further processed in stretch blow molding machines to create final PET bottles.

The applications of PET preform machines are primarily centered around the packaging industry. The preforms produced by these machines serve as the starting point for the production of a diverse range of PET bottles and containers used for various purposes. The beverages industry, including carbonated drinks, juices, bottled water, and energy drinks, is a major consumer of PET bottles. Additionally, PET containers find use in the packaging of edible oils, sauces, condiments, personal care products such as shampoos and lotions, household cleaning products, and more. The versatility of PET packaging, combined with its aesthetic appeal and barrier properties, makes it suitable for both single-use and reusable applications. As a result, PET preform machines play a crucial role in facilitating the efficient and cost-effective production of PET containers for a wide array of consumer goods.

The PET preform machines market has experienced robust growth driven by several key factors. The rising demand for PET bottles across various industries, particularly the beverage and packaged food sectors, has been a primary driver. PET bottles are favored for their lightweight, durability, and recyclability, aligning with consumer preferences for convenient and sustainable packaging. This demand surge has led to an increased need for efficient and high-output PET preform machines to meet the production requirements of these bottles. Moreover, technological advancements have significantly impacted the PET preform machines market. Manufacturers have been investing in research and development to enhance machine automation, precision, and energy efficiency.

PET Preform Machines Market Segmentation

The global PET Preform Machines Market segmentation is based on technology, number of cavities, application, end-use, and geography.

PET Preform Machines Market By Technology

- Stretch blow molding

- Injection molding

According to the PET preform machines industry analysis, the injection molding segment accounted for the largest market share in 2022. Injection molding is a crucial step in the production of PET preforms, forming the foundation for creating high-quality PET bottles and containers. The demand for PET bottles, particularly in the beverage and packaged goods industries, has been a primary driver of growth in this segment. As consumer preferences gravitate towards lightweight, shatter-resistant, and environmentally-friendly packaging, PET bottles have emerged as a preferred choice. This surge in demand has necessitated advanced injection molding processes to produce PET preforms efficiently and with exceptional quality.

PET Preform Machines Market By Number of Cavities

- Multiple cavity

- Single cavity

In terms of number of cavitiess, the multiple cavity segment is expected to witness significant growth in the coming years. Multiple cavity molds are designed to create multiple PET preforms in a single mold, effectively increasing the yield per cycle. This approach aligns well with the demand for high-volume production in industries such as beverages, where PET bottles are a staple packaging solution. The ability to produce multiple preforms simultaneously reduces production time and energy consumption, making it an attractive option for manufacturers seeking cost-effective and streamlined operations. One of the key drivers of growth in the multiple cavity segment is the rapid expansion of consumer goods industries. The increasing consumption of beverages, packaged foods, personal care products, and other goods has necessitated higher production rates to meet market demand.

PET Preform Machines Market By Application

- Carbonated Beverages

- Alcoholic Beverages

- Edible Oil

- Bottled Water

- Non-Carbonated Beverages

- Others

According to the PET preform machines market forecast, the carbonated beverages segment is expected to witness significant growth in the coming years. Carbonated beverages, such as soft drinks and sparkling water, have maintained their popularity despite changing consumption patterns, and PET bottles have become the preferred packaging choice for these products. This demand has directly contributed to the growth of PET preform machines tailored for the carbonated beverages segment. One of the driving factors behind this growth is the need for packaging solutions that maintain the carbonation and freshness of beverages. PET bottles offer excellent barrier properties, effectively preserving carbonation and preventing gas permeation. As consumers continue to seek convenience and portability, PET bottles for carbonated beverages have become essential in the market.

PET Preform Machines Market By End-use

- Beverages

- Pharmaceuticals

- Food

- Chemicals & Petrochemicals

- Personal Care & Cosmetics

- Others

Based on the end-use, the beverages segment is expected to continue its growth trajectory in the coming years. The global beverage industry, encompassing water, soft drinks, juices, energy drinks, and more, has seen a continuous rise in demand. As consumers increasingly prioritize convenience, portability, and sustainable packaging options, PET bottles have emerged as a preferred choice. This shift has driven the demand for PET preform machines capable of producing bottles tailored to the diverse requirements of the beverages segment. One of the main drivers of growth in this segment is the innovation in product offerings. Beverage manufacturers are constantly introducing new flavors, packaging sizes, and functional beverages to meet evolving consumer preferences.

PET Preform Machines Market Regional Outlook

North America

- U.S.

- Canada

Europe

- U.K.

- Germany

- France

- Spain

- Rest of Europe

Asia-Pacific

- India

- Japan

- China

- Australia

- South Korea

- Rest of Asia-Pacific

Latin America

- Brazil

- Mexico

- Rest of Latin America

The Middle East & Africa

- South Africa

- GCC Countries

- Rest of the Middle East & Africa (ME&A)

PET Preform Machines Market Regional Analysis

The Asia-Pacific region has emerged as the dominating force in the PET preform machines market due to a combination of factors that create a conducive environment for growth and development. One of the key drivers is the region's thriving consumer goods and packaging industries. With a rapidly growing population and rising disposable incomes, there is an increasing demand for beverages, packaged foods, personal care products, and more. This demand has led to a significant need for PET bottles, which in turn fuels the demand for PET preform machines. As a result, manufacturers in the Asia-Pacific region have strategically invested in PET preform machine technologies to meet this expanding market demand. Additionally, the Asia-Pacific region benefits from a strong manufacturing base and favorable economic conditions. The presence of several emerging economies, such as China, India, and Southeast Asian nations, provides a competitive advantage in terms of production capabilities and cost-effectiveness. This has attracted both domestic and international players to invest in PET preform machine manufacturing and assembly facilities within the region, further driving its dominance in the market.

PET Preform Machines Market Player

Some of the top PET preform machines market companies offered in the professional report include Husky Injection Molding Systems, SIPA S.p.A., Nissei ASB Machine Co., Ltd., Sacmi Group, Netstal-Machinery Ltd., Krones AG, KraussMaffei Group, Sidel Group, Chumpower Machinery Corp., Powerjet Plastic Machinery Co., Ltd., Demark Holding Group, and Jon Wai Machinery Works Co., Ltd.

Frequently Asked Questions

What was the market size of the global PET preform machines in 2022?

What was the market size of the global PET preform machines in 2022?

What is the CAGR of the global PET preform machines market from 2023 to 2032?

The CAGR of PET preform machines is 5.9% during the analysis period of 2023 to 2032.

Which are the key players in the PET preform machines market?

The key players operating in the global market are including Husky Injection Molding Systems, SIPA S.p.A., Nissei ASB Machine Co., Ltd., Sacmi Group, Netstal-Machinery Ltd., Krones AG, KraussMaffei Group, Sidel Group, Chumpower Machinery Corp., Powerjet Plastic Machinery Co., Ltd., Demark Holding Group, and Jon Wai Machinery Works Co., Ltd.

Which region dominated the global PET preform machines market share?

Asia-Pacific held the dominating position in PET preform machines industry during the analysis period of 2023 to 2032.

Which region registered fastest CAGR from 2023 to 2032?

North America region exhibited fastest growing CAGR for market of PET preform machines during the analysis period of 2023 to 2032.

What are the current trends and dynamics in the global PET preform machines industry?

The current trends and dynamics in the PET preform machines industry include growing demand for PET bottles in the food and beverage industry, and increasing preference for lightweight and transparent packaging solutions.

Which technology held the maximum share in 2022?

The injection molding technology held the maximum share of the PET preform machines industry.