Machine Condition Monitoring Market Size - Global Industry, Share, Analysis, Trends and Forecast 2023 - 2032

Published :

Report ID:

Pages :

Format :

Machine Condition Monitoring Market Size - Global Industry, Share, Analysis, Trends and Forecast 2023 - 2032

Report Coverage

- Industry Dynamics

- Market Size and Forecast Data

- Segment Analysis

- Competitive Landscape

- Regional Analysis with a Niche Focus on Country-Level Data

- High Level Analysis - Porter's, PESTEL, Value Chain, etc.

- Company Profiles of Key Players

- Option to Customize the Report As Per Your Specific Need

Request Sample Report

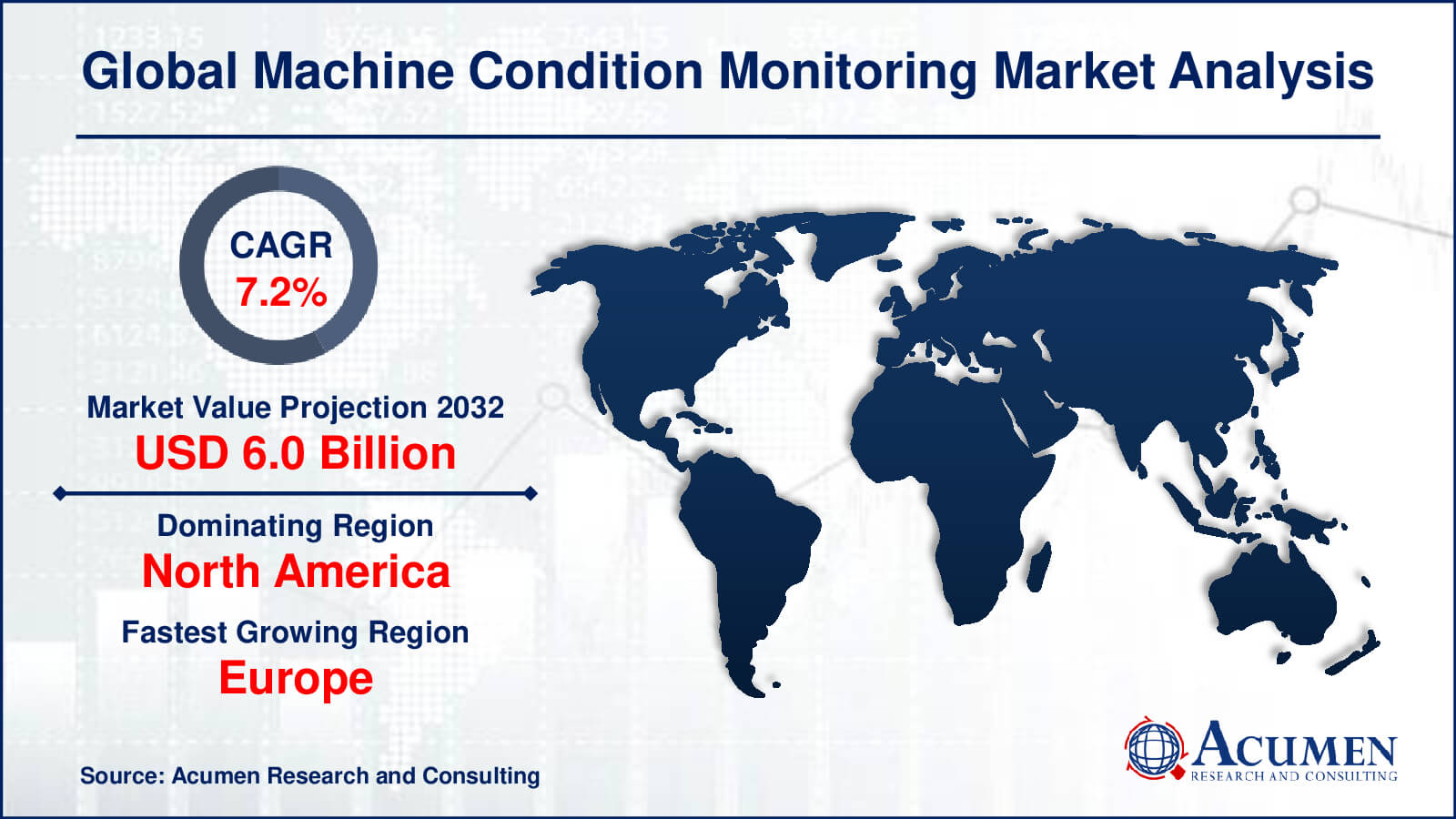

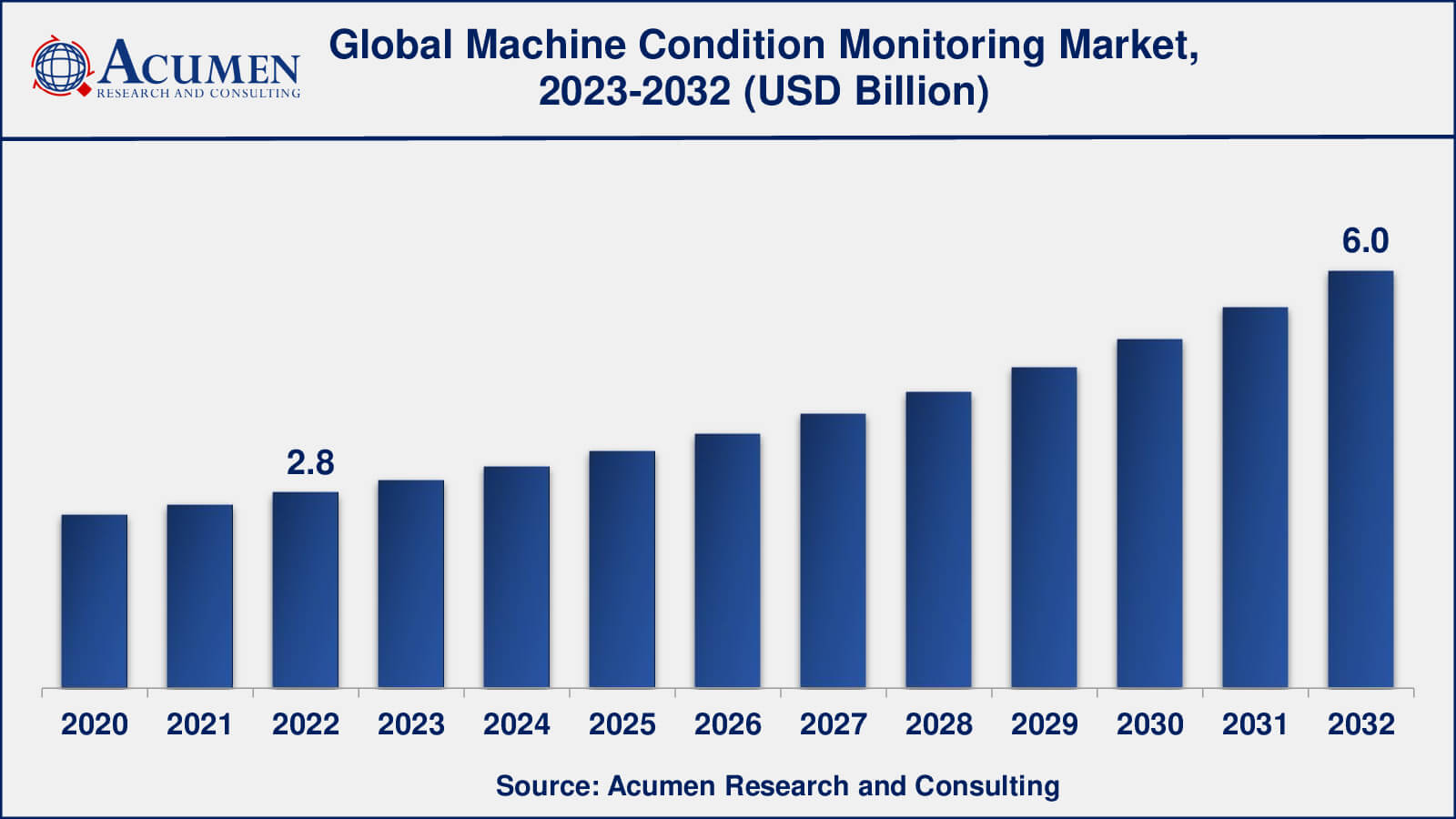

The Global Machine Condition Monitoring Market Size collected USD 2.8 Billion in 2022 and is set to achieve a market size of USD 6.0 Billion in 2032 growing at a CAGR of 7.2% from 2023 to 2032.

Machine Condition Monitoring Market Report Statistics

- Global machine condition monitoring market revenue is estimated to reach USD 6.0 billion by 2032 with a CAGR of 7.2% from 2023 to 2032

- North America machine condition monitoring market value occupied more than USD 1 billion in 2022

- Europe machine condition monitoring market growth will record a CAGR of more than 7% from 2023 to 2032

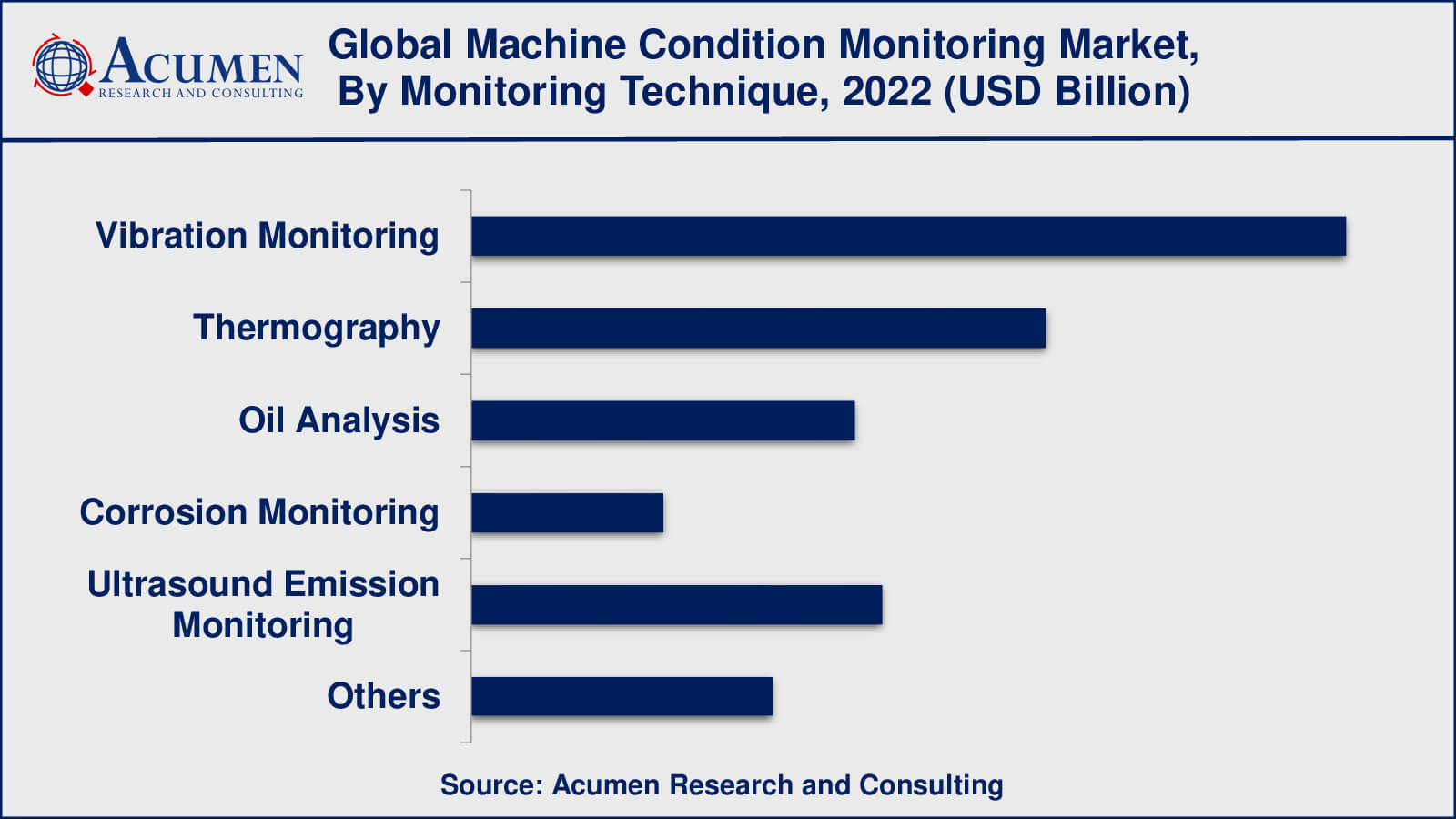

- Among monitoring technique, the vibration monitoring sub-segment generated around 32% share in 2022

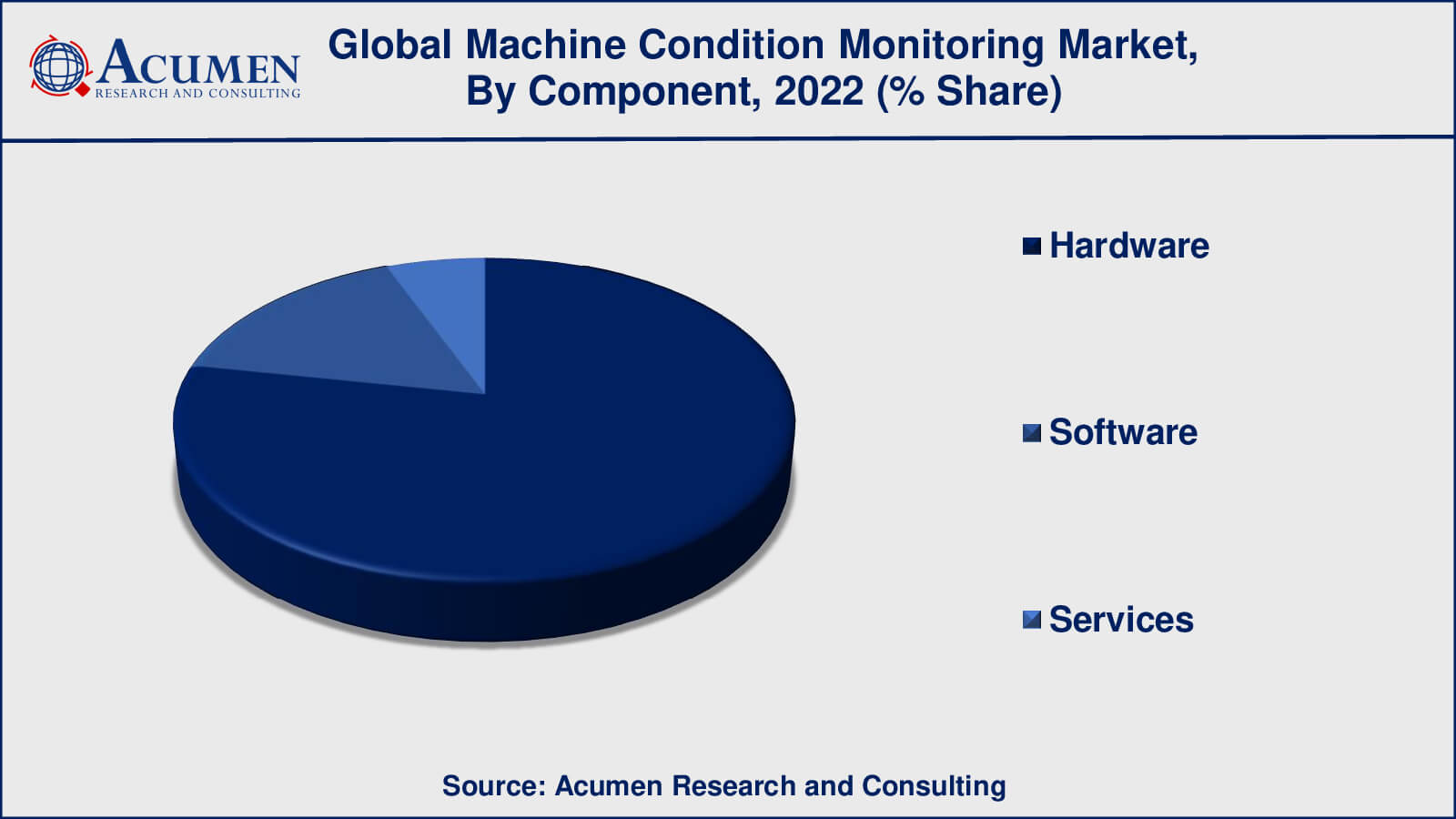

- Based on component, the hardware generated around US$ 2.2 billion revenue in 2022

- Integration with Industry 4.0 technologies is a popular machine condition monitoring market trend that fuels the industry demand

The technique of machine condition monitoring is used widely to find any fault or failure in a machine such as vibration, noise, and temperature measurements. Some of the key factors such as an increase in demand for diminished maintenance costs coupled with unexpected faults and failure are anticipated to augment the growth of the global machine condition monitoring market over the forecast period. Machine condition monitoring procedures are widely used in pumps, rotating equipment, internal combustion engines, electric motors, and presses among others. Machine condition monitoring is a crucial part of the process of predictive maintenance.

Global Machine Condition Monitoring Market Dynamics

Market Drivers

- Increasing demand for predictive maintenance

- Growing need for operational efficiency

- Rising adoption of industrial automation

- Increasing awareness about the benefits of machine condition monitoring

Market Restraints

- High implementation and maintenance costs

- Concerns about data security and privacy

Market Opportunities

- Increasing focus on safety and regulatory compliance

- Growing demand for cloud-based solutions

Machine Condition Monitoring Market Report Coverage

| Market | Machine Condition Monitoring Market |

| Machine Condition Monitoring Market Size 2022 | USD 2.8 Billion |

| Machine Condition Monitoring Market Forecast 2032 | USD 6.0 Billion |

| Machine Condition Monitoring Market CAGR During 2023 - 2032 | 7.2% |

| Machine Condition Monitoring Market Analysis Period | 2020 - 2032 |

| Machine Condition Monitoring Market Base Year | 2022 |

| Machine Condition Monitoring Market Forecast Data | 2023 - 2032 |

| Segments Covered | By Monitoring Technique, By Monitoring Process, By Component, By Deployment, By End-Use, And By Geography |

| Regional Scope | North America, Europe, Asia Pacific, Latin America, and Middle East & Africa |

| Key Companies Profiled | ALS, Emerson Electric Co., General Electric, Honeywell International Inc., Megget PLC, National Instruments Corp., Parker Hannifin, Rockwell Automation, Inc., Schaeffler AG., and SKF AB. |

| Report Coverage |

Market Trends, Drivers, Restraints, Competitive Analysis, Player Profiling, Covid-19 Analysis, Regulation Analysis |

Machine Condition Monitoring Market Growth Factors

With the continuously rising population, the usage of technologies such as wireless communication in heating, ventilation, and air conditioning (HVAC) is anticipated to increase significantly. This is expected to create a need for monitoring the health of associated machines for ensuring the flawless functioning of the entire system, thus bolstering the growth of the machine conditioning monitoring market. In addition, the trend of Industry 4.0 or smart factory as well as the transition from predictive to preventative maintenance is expected to further add to the growth of the machine condition monitoring market over the forecast period. In addition, advancements in technology such as direct communication processes, expansion in low cost advanced machine condition monitoring systems as well as rapid processing functions are anticipated to open new avenues for the growth of the global machine condition monitoring market. The major benefits offered by machine condition monitoring include improved reliability by the use of effective prediction of faults and failures as well as maximizing the overall life of machines by providing proper scheduling of maintenance cycles as well as achieving a significant reduction in frequency along with the severity of machine downtimes among others.

Machine Condition Monitoring Market Segmentation

The worldwide machine condition monitoring market is categorized based on monitoring technique, monitoring process, component, deployment, end-use, and geography.

Machine Condition Monitoring Market By Monitoring Technique

- Vibration Monitoring

- Thermography

- Oil Analysis

- Corrosion Monitoring

- Ultrasound Emission Monitoring

- Others

According to the machine condition monitoring market forecast, vibration monitoring is the most widely used machine condition monitoring technique in a variety of industries. Vibration monitoring entails using vibration sensors to measure and analyze equipment vibration patterns, allowing maintenance teams to identify potential problems before they turn into costly failures. Vibration monitoring is especially useful for detecting faults in rotating equipment like motors, pumps, and gearboxes.

Thermography, which includes using infrared cameras to determine the temperature of equipment and detect anomalies, is another technique commonly used in machine condition monitoring, especially for electrical and mechanical systems. Machine condition monitoring techniques such as corrosion monitoring, oil analysis, and ultrasound emission monitoring are also widely used, but their adoption varies depending on the type of hardware being monitored and the industry in which it is used.

Machine Condition Monitoring Market By Monitoring Process

- Online

- Portable

The online monitoring process is the market leader in machine condition monitoring because it allows for continuous real-time monitoring of equipment health, allowing maintenance teams to identify potential issues early and avoid unplanned downtime. Online monitoring systems are typically permanently installed on equipment and use sensors to continuously collect data, which is then transmitted to a central monitoring system for analysis.

Portable monitoring systems, on the other hand, are intended for sporadic use and are frequently used to supplement online monitoring systems. Portable monitoring systems are typically smaller, more portable, but less expensive than online monitoring systems, which makes them perfect for monitoring equipment that is not constantly in use or in remote locations. Portable systems may also be used for spot checks or to verify data collected by online systems.

Machine Condition Monitoring Market By Component

- Hardware

- Software

- Services

According to machine condition monitoring industry analysis, the hardware component will have a significant market share in 2022. The hardware component, which includes sensors, monitors, and other hardware required for machine condition monitoring, is also a significant component of the market, but its growth is dependent on the adoption of machine condition monitoring systems. In terms of revenue, the services component leads the machine condition monitoring market, as it includes a variety of services such as consulting, training, installation, maintenance, and support. Services are critical for the successful setup and maintenance of machine condition monitoring systems, and they frequently entail ongoing collaboration between customers and service providers.

Machine Condition Monitoring Market By Deployment

- Cloud

- On-Premises

The on-premises deployment currently dominates the machine condition monitoring market. On-premises deployment entails installing machine condition monitoring systems on-site, which frequently make use of dedicated hardware and software that is installed locally. This approach gives businesses complete control over their data and systems while also providing greater flexibility and customization options. On-premises deployment is frequently preferred by businesses with stringent data security and compliance requirements, as well as those operating in industries with limited connectivity or intermittent internet access.

Cloud deployment, on the other hand, is expected to grow rapidly in the machine condition monitoring market due to numerous benefits such as scalability, flexibility, and lower upfront costs. Cloud-based machine condition monitoring systems collect, store, and analyse data on remote servers, which users can access from anywhere with an internet connection. Cloud deployment is especially beneficial for small and medium-sized businesses, which may lack the resources or expertise to establish and maintain on-premises systems.

Machine Condition Monitoring Market By End-Use

- Power Generation

- Automotive

- Oil & Gas

- Metal & Mining

- Aerospace

- Food & Beverages

- Chemicals

- Marine

- Others

The machine condition monitoring market is currently dominated by the power generation sector. Power generation facilities, such as power plants, wind farms, and solar farms, heavily rely on large and complex machinery and equipment that must be constantly monitored in order to ensure reliable operation and avoid unplanned downtime. Machine condition monitoring systems are essential for detecting potential problems and allowing maintenance teams to address them before they cause equipment failure and costly downtime.

Because it involves the operation of critical and quite often remote equipment such as drilling rigs, pipelines, and refineries, the oil and gas industry is a significant end-use segment in the machine condition monitoring market. Machine condition monitoring systems detect potential issues like equipment wear and corrosion, allowing maintenance teams to address them proactively and avoid unplanned downtime.

The machine condition monitoring market also includes significant end-use segments from the automotive, aerospace, metals, and mining industries. These industries rely on sophisticated machinery and equipment to produce and process materials and products, and downtime can be extremely costly.

Machine Condition Monitoring Market Regional Outlook

North America

- U.S.

- Canada

Europe

- U.K.

- Germany

- France

- Spain

- Rest of Europe

Asia-Pacific

- India

- Japan

- China

- Australia

- South Korea

- Rest of Asia-Pacific

Latin America

- Brazil

- Mexico

- Rest of Latin America

The Middle East & Africa

- South Africa

- GCC Countries

- Rest of the Middle East & Africa (ME&A)

Machine Condition Monitoring Market Regional Analysis

The presence of several key market players, strong government initiatives to promote Industry 4.0, and widespread adoption of advanced technologies are expected to propel North America to the top of the machine condition monitoring market. The major contributors to North American market growth are the United States and Canada.

Europe is projected to be the second-biggest market for machine condition monitoring, owing to the widespread adoption of advanced technologies, increased demand for predictive maintenance solutions, and a greater emphasis on improving operational efficiency. Germany, France, and the United Kingdom are major contributors to the expansion of the European market.

Because of rapid industrialization, rising adoption of smart manufacturing technologies, and the presence of several key market players, the Asia-Pacific region is projected to experience substantial development in the machine condition monitoring market. China, Japan, India, and South Korea are the major contributors to the Asia-Pacific market's expansion.

Machine Condition Monitoring Market Players

Some of the global machine condition monitoring companies profiled in the report include ALS, Emerson Electric Co., General Electric, Honeywell International Inc., Megget PLC, National Instruments Corp., Parker Hannifin, Rockwell Automation, Inc., Schaeffler AG., and SKF AB.

Frequently Asked Questions

What was the market size of the global machine condition monitoring in 2022?

The market size of machine condition monitoring was USD 2.8 Billion in 2022.

What is the CAGR of the global machine condition monitoring market during forecast period of 2023 to 2032?

The CAGR of machine condition monitoring market is 7.2% during the analysis period of 2023 to 2032.

Which are the key players operating in the market?

The key players operating in the global market are include ALS, Emerson Electric Co., General Electric, Honeywell International Inc., Megget PLC, National Instruments Corp., Parker Hannifin, Rockwell Automation, Inc., Schaeffler AG., and SKF AB.

Which region held the dominating position in the global machine condition monitoring market?

North America held the dominating position in machine condition monitoring market during the analysis period of 2023 to 2032.

Which region registered the fastest growing CAGR for the forecast period of 2023 to 2032?

Europe region exhibited fastest growing CAGR for machine condition monitoring market during the analysis period of 2023 to 2032.

What are the current trends and dynamics in the global machine condition monitoring market?

The current trends and dynamics in the machine condition monitoring industry include increasing demand for predictive maintenance, growing need for operational efficiency, and rising adoption of industrial automation.

Which component held the maximum share in 2022?

The hardware component held the maximum share of the machine condition monitoring market.