Coal Tar Pitch Market | Acumen Research and Consulting

Coal Tar Pitch Market Size - Global Industry, Share, Analysis, Trends and Forecast 2024 - 2032

Published :

Report ID:

Pages :

Format : ![]()

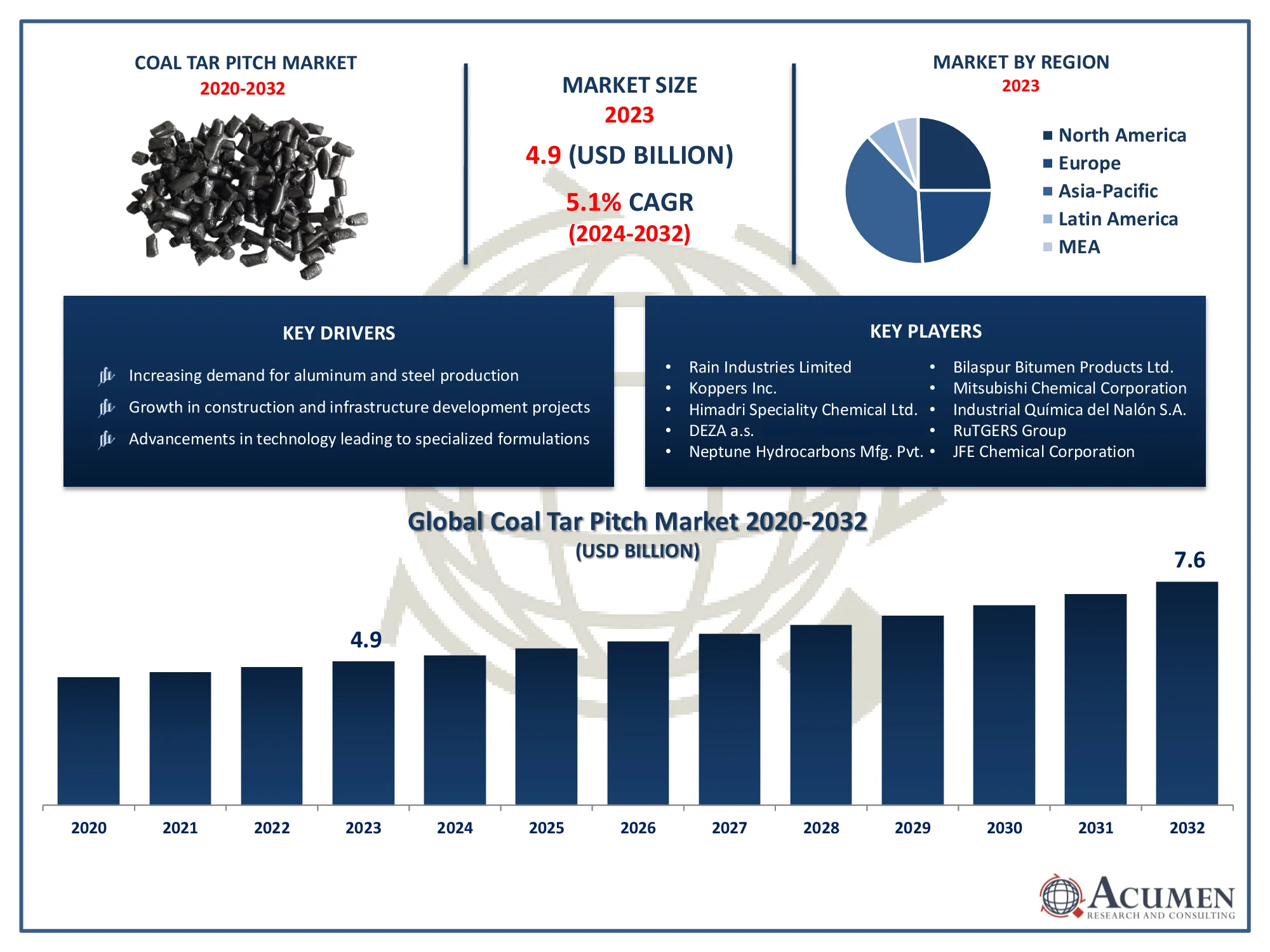

The Coal Tar Pitch Market Size accounted for USD 4.9 Billion in 2023 and is projected to achieve a market size of USD 7.6 Billion by 2032 growing at a CAGR of 5.1% from 2024 to 2032.

Coal Tar Pitch Market Highlights

- Global coal tar pitch market revenue is expected to increase by USD 7.6 Billion by 2032, with a 5.1% CAGR from 2024 to 2032

- Asia-Pacific region led with more than 60% of coal tar pitch market share in 2023

- Asia-Pacific coal tar pitch market growth will record a CAGR of more than 6.3% from 2024 to 2032

- By grade, the blinder & impregnation pitch segment has captured more than 59% of market share in 2023

- By application, aluminum smelting is one of the largest and fastest-growing segments of the coal tar pitch industry

- Increasing demand for aluminum and steel production, drives the coal tar pitch market value

Coal tar pitch is a dark, viscous substance obtained as a byproduct during the process of coal tar distillation. It primarily consists of aromatic hydrocarbons, heterocyclic compounds, and phenols. Due to its high carbon content and adhesive properties, coal tar pitch finds extensive use as a binding agent in the production of carbon anodes for aluminum smelting, graphite electrodes for electric arc furnaces, and as a base material in the manufacturing of high-quality carbon and graphite products used in various industries such as steel, aerospace, and automotive.

The market for coal tar pitch has seen significant growth in recent years, driven by the increasing demand for aluminum and steel worldwide. With the expansion of industries like construction, automotive, and infrastructure development, the need for aluminum and steel products has surged, consequently boosting the demand for coal tar pitch as a key component in their manufacturing processes. Additionally, advancements in technology have led to the development of specialized coal tar pitch formulations tailored to meet the stringent requirements of modern industrial applications, further expanding its market potential.

Global Coal Tar Pitch Market Trends

Market Drivers

- Increasing demand for aluminum and steel production

- Growth in construction and infrastructure development projects

- Advancements in technology leading to specialized formulations

- Rising focus on sustainable practices and material recycling

- Expansion of carbon and graphite product applications in various industries

Market Restraints

- Environmental concerns associated with coal tar byproducts

- Volatility in raw material prices affecting production costs

Market Opportunities

- Exploration of novel applications and product innovations

- Adoption of advanced processing techniques for higher efficiency

Coal Tar Pitch Market Report Coverage

| Market | Coal Tar Pitch Market |

| Coal Tar Pitch Market Size 2022 |

USD 4.9 Billion |

| Coal Tar Pitch Market Forecast 2032 | USD 7.6 Billion |

| Coal Tar Pitch Market CAGR During 2023 - 2032 | 5.1% |

| Coal Tar Pitch Market Analysis Period | 2020 - 2032 |

| Coal Tar Pitch Market Base Year |

2022 |

| Coal Tar Pitch Market Forecast Data | 2023 - 2032 |

| Segments Covered | By Grade, By Application, And By Geography |

| Regional Scope | North America, Europe, Asia Pacific, Latin America, and Middle East & Africa |

| Key Companies Profiled | Rain Industries Limited, Koppers Inc., Himadri Speciality Chemical Ltd., DEZA a.s., Neptune Hydrocarbons Mfg. Pvt., Bilaspur Bitumen Products Ltd., Mitsubishi Chemical Corporation, Industrial Química del Nalón S.A., Shanghai Baosteel Chemical Co., Ltd., RuTGERS Group, JFE Chemical Corporation, and Nippon Steel Chemical Co., Ltd. |

| Report Coverage |

Market Trends, Drivers, Restraints, Competitive Analysis, Player Profiling, Covid-19 Analysis, Regulation Analysis |

Coal tar pitch is a viscous, black liquid obtained as a byproduct during the distillation of coal to produce coke or gas. It primarily consists of aromatic hydrocarbons and compounds, making it highly adhesive and durable. One of its key applications is in the production of carbon and graphite materials. Due to its high carbon content and excellent binding properties, coal tar pitch is extensively used as a binder in the manufacturing of carbon anodes for aluminum smelting, graphite electrodes for electric arc furnaces, and a range of other carbon and graphite products used in industries such as steel, aerospace, and automotive. In the aluminum industry, coal tar pitch plays a critical role in the production of carbon anodes used in the electrolytic process of aluminum smelting. The pitch binds together aggregates and other materials to form solid carbon anodes capable of withstanding high temperatures and corrosive environments.

The coal tar pitch market has witnessed steady growth in recent years, driven by its integral role in various industrial sectors. The increasing demand for aluminum and steel production, fueled by global infrastructure development and urbanization projects, has been a primary driver of market growth. Coal tar pitch serves as a crucial binding agent in the production of carbon anodes for aluminum smelting and graphite electrodes for electric arc furnaces used in steel manufacturing, thus positioning itself as a vital component in these value chains. Additionally, the expanding applications of carbon and graphite products across industries such as aerospace, automotive, and electronics have further propelled the demand for coal tar pitch. Moreover, technological advancements and innovations in coal tar pitch formulations have unlocked new opportunities for market expansion. Manufacturers are investing in research and development to develop specialized formulations that cater to specific industrial requirements, such as enhanced durability, conductivity, and thermal stability.

Coal Tar Pitch Market Segmentation

The global Coal Tar Pitch Market segmentation is based on grade, application, and geography.

Coal Tar Pitch Market By Grade

- Blinder & Impregnation Pitch

- Industrial Pitch

In terms of grades, the blinder & impregnation pitch segment accounted for the largest market share in 2023. Blinder pitch, also known as binder pitch, is primarily used in the production of carbon and graphite electrodes, which are essential components in electric arc furnaces for steel manufacturing. As the global demand for steel continues to rise, driven by infrastructure development and industrialization, the demand for blinder pitch as a binding agent in electrode production has surged, consequently fueling segment growth. Additionally, impregnation pitch is utilized in the impregnation process of carbon and graphite materials to enhance their mechanical properties, electrical conductivity, and resistance to chemical corrosion. This segment has witnessed growth propelled by the increasing demand for high-performance carbon and graphite products in applications such as aerospace, automotive, and electronics. Furthermore, advancements in pitch manufacturing technology and formulation have contributed to the growth of the blinder and impregnation pitch segment.

Coal Tar Pitch Market By Application

- Aluminum Smelting

- Roofing and Pavement

- Electrodes

- Carbon Fiber

- Refractories

- Others

According to the coal tar pitch market forecast, the aluminum smelting segment is expected to witness significant growth in the coming years. Coal tar pitch serves as a critical component in the production of carbon anodes used in the electrolytic reduction process to extract aluminum from alumina. These anodes, formed by blending coal tar pitch with aggregates and other additives, play a pivotal role in conducting electricity and facilitating the electrolysis process within aluminum smelting cells. As the automotive, aerospace, construction, and packaging sectors continue to demand lightweight and corrosion-resistant aluminum products, the requirement for high-quality carbon anodes produced with coal tar pitch is expected to escalate. Furthermore, technological advancements and process innovations in aluminum smelting have propelled the demand for coal tar pitch with enhanced properties such as higher thermal stability, electrical conductivity, and mechanical strength.

Coal Tar Pitch Market Regional Outlook

North America

- U.S.

- Canada

Europe

- U.K.

- Germany

- France

- Spain

- Rest of Europe

Asia-Pacific

- India

- Japan

- China

- Australia

- South Korea

- Rest of Asia-Pacific

Latin America

- Brazil

- Mexico

- Rest of Latin America

The Middle East & Africa

- South Africa

- GCC Countries

- Rest of the Middle East & Africa (ME&A)

Coal Tar Pitch Market Regional Analysis

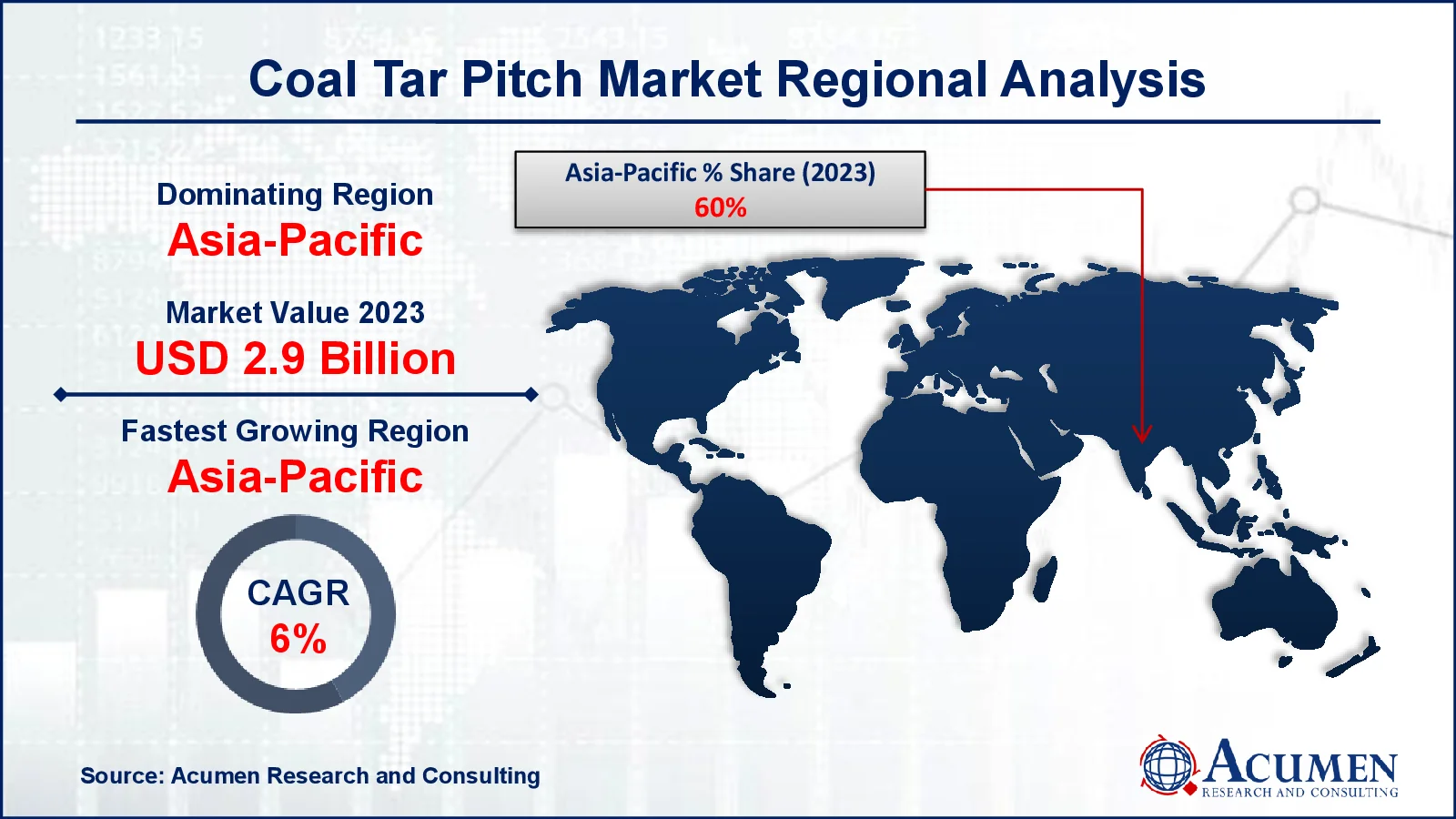

The Asia-Pacific region has emerged as a dominating force in the coal tar pitch market, primarily driven by the rapid industrialization and infrastructure development witnessed across countries like China, India, Japan, and South Korea. These nations are major consumers of coal tar pitch due to their significant aluminum, steel, and graphite electrode manufacturing sectors. China, in particular, holds a substantial share of the global coal tar pitch market, owing to its massive aluminum and steel production capacities. The country's robust industrial base and continued investments in infrastructure projects have sustained a consistent demand for coal tar pitch. Moreover, the Asia-Pacific region benefits from abundant coal resources, which serve as the raw material for coal tar pitch production. This availability of raw materials, coupled with favorable government policies and investments in manufacturing infrastructure, has further strengthened the region's position as a dominant player in the coal tar pitch market. Additionally, the presence of key market players and a skilled workforce adept at advanced manufacturing processes contribute to the region's competitive advantage in coal tar pitch production. With the Asia-Pacific region continuing to witness economic growth and industrial expansion, it is expected to maintain its dominance in the global coal tar pitch market for the foreseeable future.

Coal Tar Pitch Market Player

Some of the top coal tar pitch market companies offered in the professional report include Rain Industries Limited, Koppers Inc., Himadri Speciality Chemical Ltd., DEZA a.s., Neptune Hydrocarbons Mfg. Pvt., Bilaspur Bitumen Products Ltd., Mitsubishi Chemical Corporation, Industrial Química del Nalón S.A., Shanghai Baosteel Chemical Co., Ltd., RuTGERS Group, JFE Chemical Corporation, and Nippon Steel Chemical Co., Ltd.

Frequently Asked Questions

What was the market size of the global coal tar pitch in 2023?

The market size of coal tar pitch was USD 4.9 Billion in 2023.

What is the CAGR of the global coal tar pitch market from 2024 to 2032?

The CAGR of coal tar pitch is 5.1% during the analysis period of 2024 to 2032.

Which are the key players in the coal tar pitch market?

The key players operating in the global market are including Rain Industries Limited, Koppers Inc., Himadri Speciality Chemical Ltd., DEZA a.s., Neptune Hydrocarbons Mfg. Pvt., Bilaspur Bitumen Products Ltd., Mitsubishi Chemical Corporation, Industrial QuÃmica del Nalón S.A., Shanghai Baosteel Chemical Co., Ltd., RuTGERS Group, JFE Chemical Corporation, and Nippon Steel Chemical Co., Ltd.

Which region dominated the global coal tar pitch market share?

Asia-Pacific held the dominating position in coal tar pitch industry during the analysis period of 2024 to 2032.

Which region registered fastest CAGR from 2024 to 2032?

Asia-Pacific region exhibited fastest growing CAGR for market of coal tar pitch during the analysis period of 2024 to 2032.

What are the current trends and dynamics in the global coal tar pitch industry?

The current trends and dynamics in the coal tar pitch market growth include increasing demand for aluminum and steel production, and growth in construction and infrastructure development projects.

Which grade held the maximum share in 2023?

The blinder & impregnation pitch grade held the maximum share of the coal tar pitch industry.