Atomic Layer Deposition Market Size - Global Industry, Share, Analysis, Trends and Forecast 2023 - 2032

Published :

Report ID:

Pages :

Format :

Atomic Layer Deposition Market Size - Global Industry, Share, Analysis, Trends and Forecast 2023 - 2032

Report Coverage

- Industry Dynamics

- Market Size and Forecast Data

- Segment Analysis

- Competitive Landscape

- Regional Analysis with a Niche Focus on Country-Level Data

- High Level Analysis - Porter's, PESTEL, Value Chain, etc.

- Company Profiles of Key Players

- Option to Customize the Report As Per Your Specific Need

Request Sample Report

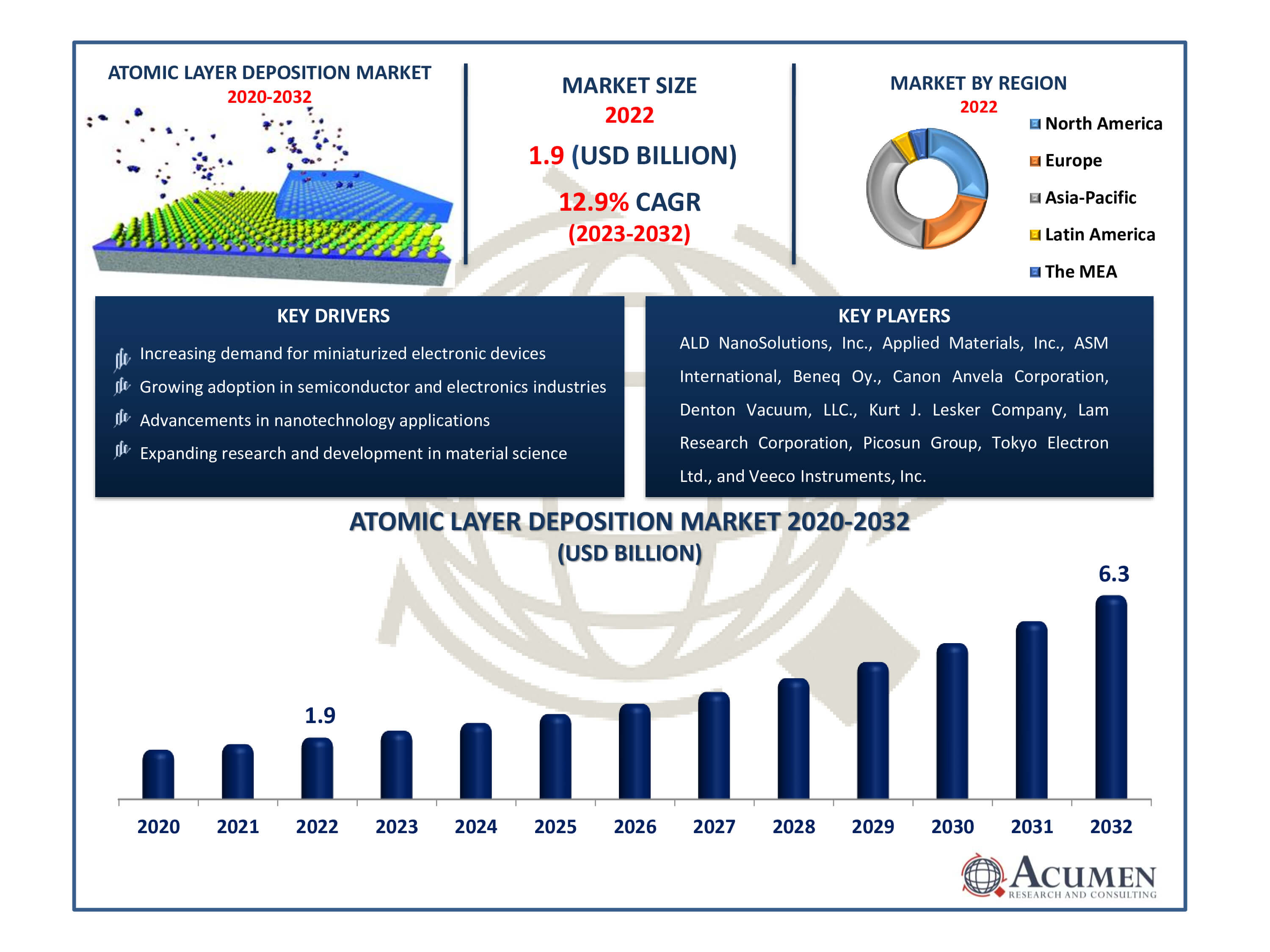

The Atomic Layer Deposition Market Size accounted for USD 1.9 Billion in 2022 and is estimated to achieve a market size of USD 6.3 Billion by 2032 growing at a CAGR of 12.9% from 2023 to 2032.

Atomic Layer Deposition Market Highlights

- Global atomic layer deposition market revenue is poised to garner USD 6.3 billion by 2032 with a CAGR of 12.9% from 2023 to 2032

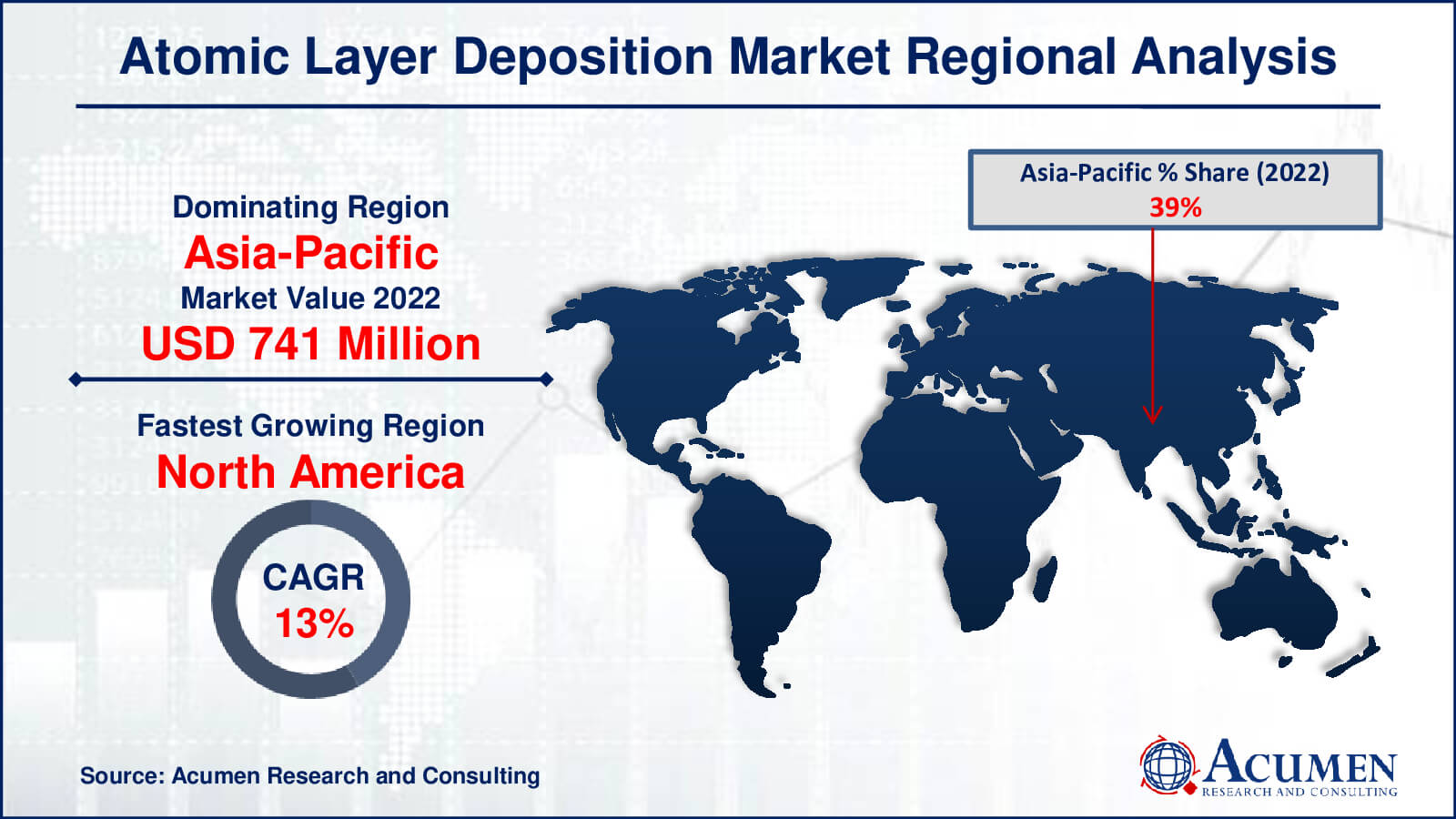

- Asia-Pacific atomic layer deposition market value occupied around USD 741 million in 2022

- North America atomic layer deposition market growth will record a CAGR of more than 13% from 2023 to 2032

- Among product, the aluminum oxide sub-segment generated over US$ 608 million revenue in 2022

- Based on application, the semiconductors & electronics sub-segment generated around 44% share in 2022

- Expansion of ALD in aerospace and automotive industries for specialized coatings is a popular atomic layer deposition market trend that fuels the industry demand

Atomic Layer Deposition (ALD) is a critical process in semiconductor equipment manufacturing, serving as a key component in the suite of instruments used to synthesize nanotechnological materials. ALD is regarded as one of the best processes for producing thin, conformal films due to its precision. This technology enables unprecedented uniformity and accuracy in the deposition process by allowing exact control at the atomic level during film growth. ALD is important in many industries, particularly semiconductor fabrication, where its ability to manufacture ultra-thin layers with atomic-level precision is widely used. Its impact is felt in a variety of industries, including electronics, optoelectronics, and catalysis, where it drives innovation in next-generation materials and device manufacture.

Global Atomic Layer Deposition Market Dynamics

Market Drivers

- Increasing demand for miniaturized electronic devices

- Growing adoption in semiconductor and electronics industries

- Advancements in nanotechnology applications

- Expanding research and development in material science

Market Restraints

- High initial setup and equipment costs

- Complexity in achieving uniform thin film deposition

- Limited material compatibility and deposition speed

Market Opportunities

- Surge in demand for energy-efficient coatings and materials

- Development of ALD for new applications like healthcare and solar cells

- Integration of ALD in emerging technologies like quantum computing

Atomic Layer Deposition Market Report Coverage

| Market | Atomic Layer Deposition Market |

| Atomic Layer Deposition Market Size 2022 | USD 1.9 Billion |

| Atomic Layer Deposition Market Forecast 2032 | USD 6.3 Billion |

| Atomic Layer Deposition Market CAGR During 2023 - 2032 | 12.9% |

| Atomic Layer Deposition Market Analysis Period | 2020 - 2032 |

| Atomic Layer Deposition Market Base Year |

2022 |

| Atomic Layer Deposition Market Forecast Data | 2023 - 2032 |

| Segments Covered | By Product, By Application, And By Geography |

| Regional Scope | North America, Europe, Asia Pacific, Latin America, and Middle East & Africa |

| Key Companies Profiled | ALD NanoSolutions, Inc., Applied Materials, Inc., ASM International, Beneq Oy., Canon Anvela Corporation, Denton Vacuum, LLC., Kurt J. Lesker Company, Lam Research Corporation, Picosun Group, Tokyo Electron Ltd., and Veeco Instruments, Inc. |

| Report Coverage |

Market Trends, Drivers, Restraints, Competitive Analysis, Player Profiling, Covid-19 Analysis, Regulation Analysis |

Atomic Layer Deposition Market Insights

The Asia-Pacific and North America regions are poised to witness significant growth in the atomic layer deposition (ALD) sector, primarily driven by the burgeoning electronics industry and the demand for semiconductor solutions. In semiconductor production, diverse deposition instruments are employed for manufacturing categories such as copper electromagnetic electrodes, dielectric high-k stacks, and copper barrier/seed layers. The escalating demand for electronic components in automobiles is anticipated to fuel the semiconductor market, thereby directly impacting the atomic layer deposition market positively.

Miniaturization stands as a recent advancement in the global electronics industry. The introduction of materials such as pore, Hf(Si)O, SiOC, ZrO, LaO, AlO, and SiC in recent years aims to enhance substrate effectiveness and stability. Emerging applications, including the rising demand for tin-sensitive solar cells, improved efficiency, and ongoing technological development, drive this trend. However, the high investment costs in research and development may hinder widespread application across various sectors. Consequently, some manufacturers favor nuclear layer deposition to produce smaller components at relatively lower costs.

Increased concerns regarding global warming and climate change have spurred governments worldwide to prioritize renewable and green energy sources. Government subsidies have significantly boosted the development of the solar power sector. Thin film materials, renowned for their efficiency and reliability, have emerged as a solution to this challenge. These materials facilitate miniaturization, contributing to the growing utilization of microcomponents within the MEMS industry. Countries like Germany, India, the United States, and the UK have introduced tax incentives and programs aimed at promoting the adoption of renewable energy sources.

The global vapor deposition industry has experienced rapid expansion, with chemical vapor deposition (CVD) holding a significant share. Additionally, epitaxy, PVD, and atomic layer deposition (ALD) represent other prominent technologies. ALD systems stand out for their advanced features, yielding high deposition performance, increased production rates, and minimal waste. ALD technology finds extensive use in high-end products across automotive, transportation, wearable health monitoring devices, and solar photovoltaic’s industries. Its significance lies in reducing production costs for cutting-edge electronic products. In specific applications, ALD technology enhances the lightness, durability, and precision of LED optic layers. Moreover, in the medical technology field, ALD-coated biosynthesized materials extend the lifespan of various medical implants.

Atomic Layer Deposition Market Segmentation

The worldwide market for atomic layer deposition is split based on product, application, and geography.

Atomic Layer Deposition Products

- Metal

- Plasma Enhanced

- Catalytic

- Aluminum Oxide

- Others

According to atomic layer deposition industry analysis, the largest product segment estimated at $608 million in 2022, is expected to continue being aluminum oxide ALD. The demand for aluminum oxide films using this deposition technique is projected to rise due to their high aluminum content, fostering industrial penetration. These films are known for their effective permeation barriers, attributed to their morphology and uniformity, without exhibiting pinhole alumina. Given its exceptional characteristics, stability across various substrates, ease of precursor material availability, and optimal metal prices, aluminum oxide film holds the largest share in this technology.

A significant trend in the industry is the technological advancements in precursor materials and substrates. This progress has led to the rapid growth of plasma-enhanced atomic layer deposition (PEALD). PEALD, known for its thickness control and superior conformity, serves as a critical enabler for logic devices and nanoscale memory.

Extensive research initiatives focusing on improved nucleation technology have led to the deposition of particulate matter and polymers. However, due to high capital costs and specific applications, this technology holds a smaller market share. For instance, ALD on polymers addresses numerous challenges related to space polymers, reducing oxygen-atom erosion rates and ultraviolet vacuum (VUV) in spacecraft polymers.

Atomic Layer Deposition Applications

- Semiconductors & Electronics

- Solar devices

- Medical equipment

- Others

The atomic layer deposition industry boasts numerous promising fields of application. In 2022, the semiconductors & electronics sector dominated, contributing to over 44% of the total revenue. The industry's shift toward semiconductor technology and the pursuit of miniaturized components has significantly propelled its development. The demand for smaller device dimensions alongside extended durability has notably expanded the application of deposition technology.

The rapid growth of the solar industry stems from evolving consumer preferences and governmental initiatives aimed at reducing greenhouse gas emissions. Atomic layer deposition finds extensive use in solar cells and devices, particularly for conformal coating. Notably, the solar devices sector is anticipated to be the fastest-growing application segment in the atomic layer deposition industry forecast period.

The substantial growth in solar energy is primarily driven by increased photovoltaic installations in economies such as China, the United States, Japan, India, Poland, and Great Britain. Countries like India and Japan are considered ideal solar markets due to their high insolation levels, elevated energy costs, growing concerns regarding greenhouse gas emissions, and relatively low electrification expenses.

Atomic Layer Deposition Market Regional Outlook

North America

- U.S.

- Canada

Europe

- U.K.

- Germany

- France

- Spain

- Rest of Europe

Asia-Pacific

- India

- Japan

- China

- Australia

- South Korea

- Rest of Asia-Pacific

Latin America

- Brazil

- Mexico

- Rest of Latin America

The Middle East & Africa

- South Africa

- GCC Countries

- Rest of the Middle East & Africa (ME&A)

Atomic Layer Deposition Market Regional Analysis

In the regional analysis of the ALD market, in 2022, Asia-Pacific emerged as the dominant region, boasting an estimated turnover surpassing USD 504 million. This ascendancy was propelled by burgeoning demand across various end-use industries like semiconductors, electronics, medical equipment, and the solar sector, enabling Asia Pacific to secure the maximum market share. Countries like China, South Korea, and Taiwan exhibited increased demand for deposition technology, leveraging their robust electronics manufacturing base. The region's growth was further augmented by the proliferation of electronic manufacturing products, substantial modernization, and the rising economies, all complemented by increased consumer electronics spending.

North America closely followed Asia Pacific in ALD market capitalization. The United States and Canada significantly contributed to regional market growth, with the United States poised for over 12% growth in the next eight years. This growth in North America is primarily driven by effective regulatory support from the government, stimulating domestic private investment and significantly impacting the semiconductor and consumer electronics sectors in the region.

Atomic Layer Deposition Market Players

Some of the top atomic layer deposition companies offered in our report includes ALD NanoSolutions, Inc., Applied Materials, Inc., ASM International, Beneq Oy., Canon Anvela Corporation, Denton Vacuum, LLC., Kurt J. Lesker Company, Lam Research Corporation, Picosun Group, Tokyo Electron Ltd., and Veeco Instruments, Inc.

Frequently Asked Questions

How big is the atomic layer deposition market?

The market size of atomic layer deposition was USD 1.9 billion in 2022.

What is the CAGR of the global atomic layer deposition market from 2023 to 2032?

The CAGR of atomic layer deposition is 12.9% during the analysis period of 2023 to 2032.

Which are the key players in the atomic layer deposition market?

The key players operating in the global market are including ALD NanoSolutions, Inc., Applied Materials, Inc., ASM International, Beneq Oy., Canon Anvela Corporation, Denton Vacuum, LLC., Kurt J. Lesker Company, Lam Research Corporation, Picosun Group, Tokyo Electron Ltd., and Veeco Instruments, Inc.

Which region dominated the global atomic layer deposition market share?

Asia-Pacific held the dominating position in atomic layer deposition industry during the analysis period of 2023 to 2032.

Which region registered fastest CAGR from 2023 to 2032?

North America region exhibited fastest growing CAGR for market of atomic layer deposition during the analysis period of 2023 to 2032.

What are the current trends and dynamics in the global atomic layer deposition industry?

The current trends and dynamics in the atomic layer deposition industry include increasing demand for miniaturized electronic devices, growing adoption in semiconductor and electronics industries, advancements in nanotechnology applications, and expanding research and development in material science.

Which product held the maximum share in 2022?

The aluminum oxide product held the maximum share of the atomic layer deposition industry.