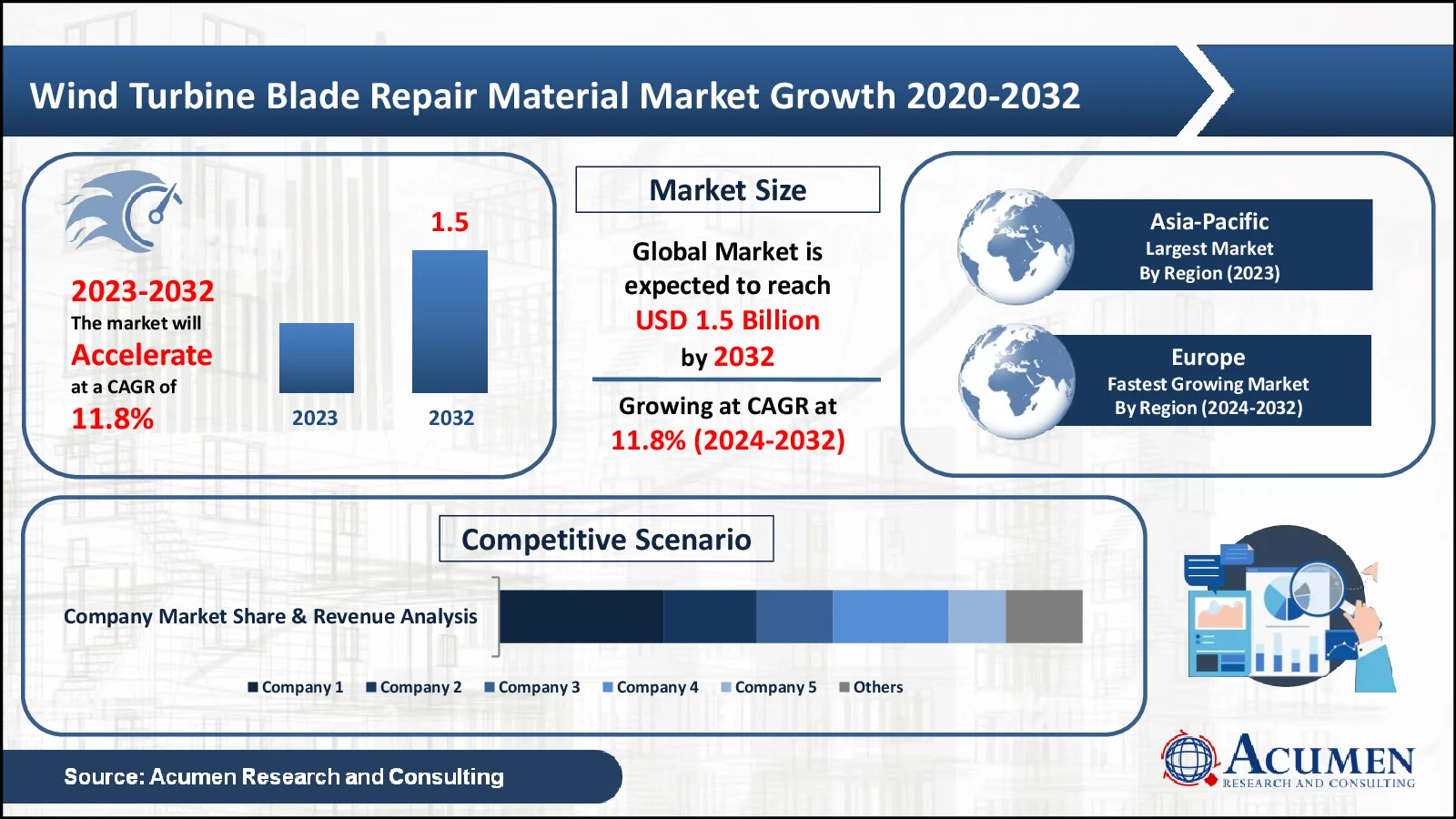

Wind Turbine Blade Repair Material Market Size Projected to Garner USD 1.5 Billion by 2032 growing at 11.8% CAGR - Exclusive Report by Acumen Research and Consulting

The Global Wind Turbine Blade Repair Material Market Size is predicted to reach USD 1.5 Billion by 2032 from USD 0.6 Billion in 2023, at a CAGR of 11.8% between 2024 and 2032, as per the Acumen Research and Consulting

In recent years, the use of advanced repair materials in wind turbine blade maintenance has surged, driven by the growing demand for renewable energy and the expansion of wind energy infrastructure globally. These materials, often composite-based, are specifically designed to address the wear and tear experienced by wind turbine blades over time due to factors like weathering, erosion, and fatigue. As wind turbines age, issues such as cracks, delamination, and surface damage become more prevalent, necessitating effective repair solutions to maintain operational efficiency and extend the lifespan of the blades.

One key factor contributing to the increased adoption of repair materials is the recognition of their cost-effectiveness and environmental benefits. Repairing damaged blades using specialized materials is often more economical than outright replacement, saving both time and resources. Moreover, repairing blades reduces the need for new blade production, which requires significant energy and raw materials, thereby reducing the overall carbon footprint of wind energy generation. As sustainability becomes a focal point in the energy sector, wind farm operators are increasingly prioritizing repair and maintenance practices that minimize environmental impact, further driving the uptake of advanced repair materials. Additionally, advancements in material science and engineering have led to the development of repair materials that offer enhanced durability, strength, and performance characteristics tailored to the unique challenges faced by wind turbine blades.

Wind Turbine Blade Repair Material Market Statistics

- Global wind turbine blade repair material market value was worth USD 0.6 Billion in 2023, with a 11.8% CAGR from 2024 to 2032

- Asia-Pacific wind turbine blade repair material market share occupied around 38% in 2023

- Europe region is expected to expand at the highest CAGR between 2024 and 2032

- By product type, the coatings segment captured the largest market share in 2023

- Aging wind turbine infrastructure necessitating maintenance, propel the wind turbine blade repair material market revenue

Access Table Of Content: https://www.acumenresearchandconsulting.com/table-of-content/wind-turbine-blade-repair-material-market

Wind Turbine Blade Repair Material Market Trends

The wind turbine blade repair material market has witnessed significant growth in recent years, driven by the rapid expansion of wind energy capacity worldwide and the need to maintain and refurbish existing turbine fleets. With an increasing number of wind turbines being installed globally, particularly in regions with favorable wind conditions, the demand for repair materials to address blade damage and degradation has surged. This growth is further fueled by the aging of existing wind turbine installations, which require ongoing maintenance and repairs to ensure optimal performance and longevity.

Moreover, technological advancements in repair materials have played a crucial role in driving market growth. Manufacturers are continually innovating to develop repair materials that offer improved durability, adhesion, and weather resistance, enabling more effective and long-lasting repairs to wind turbine blades. These materials are designed to withstand the harsh environmental conditions experienced in wind farms, including exposure to UV radiation, salt spray, and extreme temperatures. As a result, wind farm operators are increasingly turning to advanced repair materials to minimize downtime, reduce maintenance costs, and extend the service life of their turbine assets. The wind turbine blade repair material market is also benefiting from supportive government policies and incentives aimed at promoting renewable energy development and reducing greenhouse gas emissions.

Wind Turbine Blade Repair Material Market Segmentation

Acumen Research and Consulting has segmented the global wind turbine blade repair material market by product type, application, and region.

- By product type, the industry is categorized into putties, coatings, and adhesives, and sealants

- By application, the market is classified into onshore, and offshore

- By region, the market is divided into Asia-Pacific, North America, Europe, Latin America, and the MEA

Wind Turbine Blade Repair Material Market Regional Overview

According to the wind turbine blade repair material industry analysis, Europe stands out as a rapidly growing region in the wind turbine blade repair material market, driven by several factors that highlight the continent's commitment to renewable energy and sustainability. One key driver is the substantial investment in wind energy infrastructure across Europe, fueled by ambitious renewable energy targets set by the European Union (EU) member states. These targets aim to increase the share of renewable energy in the overall energy mix, with wind power playing a significant role in achieving these goals. As a result, there is a growing need for effective maintenance and repair solutions to ensure the reliable and efficient operation of existing wind turbine fleets, driving the demand for repair materials in the region. Moreover, Europe's established wind energy industry and extensive installed base of wind turbines contribute to the region's prominence in the blade repair material market. With numerous wind farms operating across Europe, particularly in countries like Germany, the United Kingdom, Spain, and Denmark, there is a sizable market for blade repair and maintenance services.

Wind Turbine Blade Repair Material Market Players

Some of the prominent wind turbine blade repair material market companies are PPG Industries Inc., Akzo Nobel N.V., The Sherwin-Williams Company, Jotun Paints, Henkel Group, Teknos Group Oy, 3M, Gurit Holding AG, Hempel A/S, Scott Bader Company Ltd., Sika AG, and Mankiewicz Gebr. and Co.

Enquire Before Buying https://www.acumenresearchandconsulting.com/inquiry-before-buying/3709

Receive our personalized services and customization by clicking here https://www.acumenresearchandconsulting.com/request-customization/3709

Mr. Richard Johnson

Acumen Research and Consulting

India: +918983225533