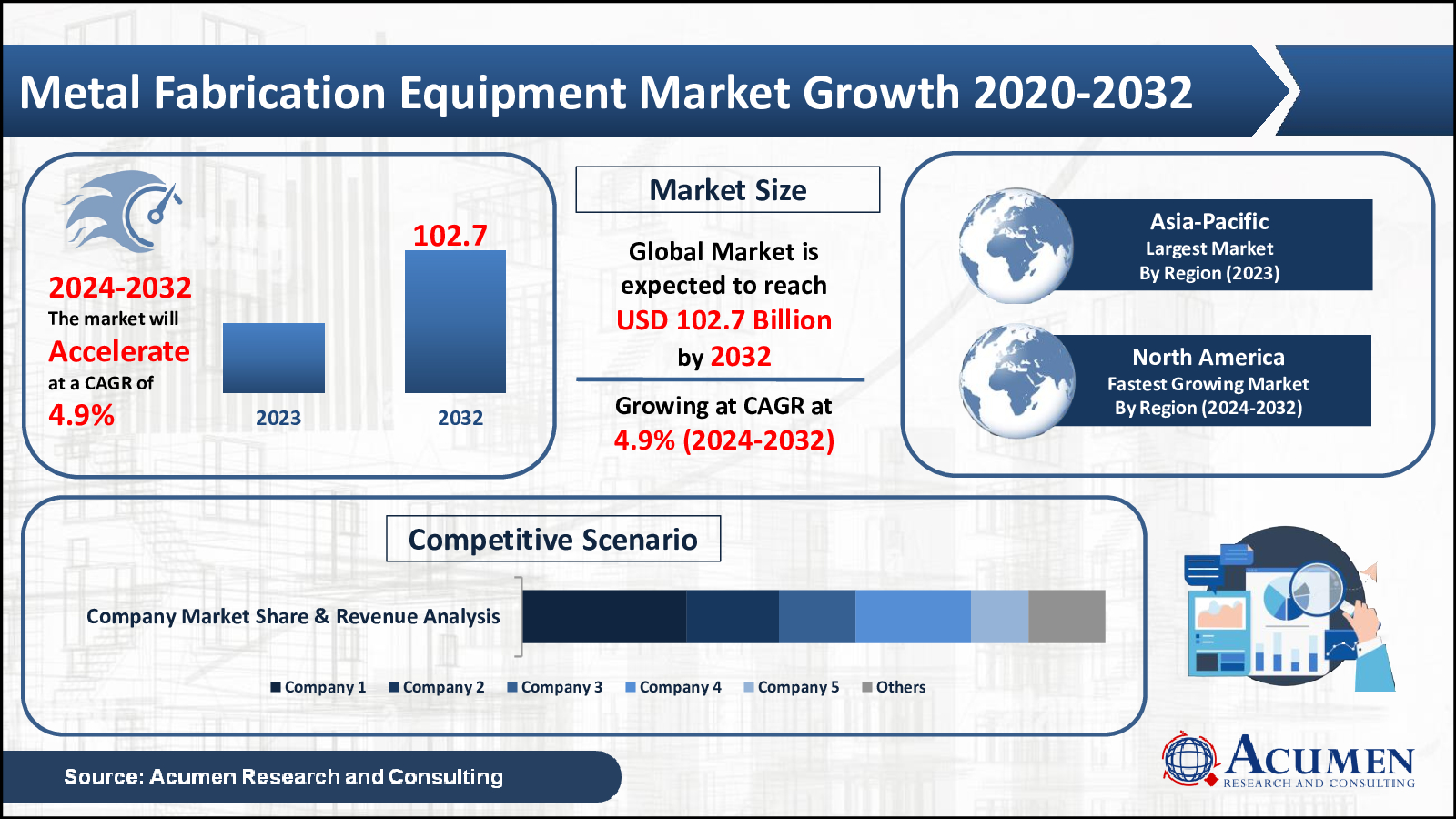

Metal Fabrication Equipment Market Size to Reach USD 102.7 Billion by 2032 growing at 4.9% CAGR - Exclusive Report by Acumen Research and Consulting

The Metal Fabrication Equipment Market, valued at USD 67.2 Billion in 2023, is anticipated to surpass USD 102.7 Billion by 2032, reflecting a projected CAGR of 4.9%

The global metal fabrication equipment market is poised for significant expansion driven by a confluence of factors including technological advancements, increasing industrialization in emerging economies, and the adoption of automation across various manufacturing sectors. Technological innovations continue to redefine the metal fabrication landscape. CNC machines, leveraging computer-aided design (CAD) and computer-aided manufacturing (CAM) software, enable precise and complex metal cutting, drilling, and forming operations with minimal human intervention. These machines are not only capable of handling a wide range of materials but also offer scalability and flexibility in production processes, catering to diverse customer demands across industries.

Laser cutting technology, known for its high-speed and accuracy, has revolutionized metal fabrication by enabling intricate designs and patterns that were previously difficult to achieve. Advances in laser technology have significantly reduced operating costs and cycle times, making it a preferred choice for industries requiring precision cutting of metals, plastics, and composites. Additionally, robotic welding systems have emerged as a cornerstone of modern manufacturing facilities, offering enhanced efficiency and consistency in weld quality. These systems automate welding processes, leading to improved productivity, reduced scrap, and enhanced workplace safety.

Furthermore, the integration of IoT (Internet of Things) and data analytics has transformed traditional metal fabrication equipment into smart machines capable of real-time monitoring, predictive maintenance, and performance optimization. Manufacturers can now monitor equipment performance remotely, diagnose potential issues before they escalate, and adjust production schedules to maximize operational efficiency. This data-driven approach not only minimizes unplanned downtime but also supports sustainable practices by optimizing energy consumption and reducing material waste.

Metal Fabrication Equipment Market Statistics

- The global metal fabrication equipment market reached USD 67.2 billion in 2023, and is projected to grow at a rate of 4.9% from 2024 to 2032

- Asia-Pacific commands a significant 44% market share, highlighting its dominance in the global market

- North America is experiencing rapid growth at 5.7%, opening up new opportunities within the market

- In 2023, the job shops application sector emerged as the dominant type within the metal fabrication equipment market

- Cutting technologies, such as laser cutting and CNC machines, played a crucial role as key revenue drivers in the market

- The aerospace and defense sectors are witnessing substantial growth trends within the metal fabrication equipment market, driven by increasing demand for precision components and structural parts

Request for a sample of this premium research report@ https://www.acumenresearchandconsulting.com/request-sample/939

Metal Fabrication Equipment Market Dynamics

Technological Advancements Fuels the Metal Fabrication Equipment Market

Technological advancements play a pivotal role in shaping the metal fabrication equipment market. Innovations such as CNC (Computer Numerical Control) machines, laser cutting technology, and robotic welding systems have revolutionized the efficiency, accuracy, and speed of metal fabrication processes. These advancements enable manufacturers to produce complex and high-precision components with reduced labor costs and improved productivity.

CNC machines, for instance, allow for automated control of machining tools via computer programs, ensuring consistent quality and faster production rates compared to conventional manual methods. Laser cutting technology offers precision cutting of various metals, increasing flexibility in design and minimizing material wastage. Robotic welding systems automate the welding process, enhancing weld quality and reducing errors.

Moreover, the integration of Internet of Things (IoT) and data analytics in metal fabrication equipment enables real-time monitoring of machines, predictive maintenance, and optimization of production schedules. These technologies not only improve operational efficiency but also reduce downtime and enhance overall equipment effectiveness (OEE). As manufacturers across industries strive to meet stringent quality standards and achieve operational excellence, the adoption of advanced metal fabrication equipment continues to rise. This trend is expected to drive the growth of the global metal fabrication equipment market in the coming years.

Growth in Emerging Economies Offers Significant Metal Fabrication Equipment Market Opportunity

One significant opportunity in the metal fabrication equipment market lies in the rapid industrialization and infrastructure development in emerging economies. Countries in Asia-Pacific, Latin America, and Africa are witnessing robust growth in sectors such as automotive, construction, and manufacturing, driving the demand for metal fabricated products. Emerging economies are increasingly investing in upgrading their manufacturing capabilities to cater to domestic demand and participate in global supply chains. This includes investments in new infrastructure projects, expansion of industrial facilities, and modernization of manufacturing processes. As a result, there is a growing need for advanced metal fabrication equipment that can deliver higher productivity, precision, and efficiency.

Government initiatives aimed at promoting local manufacturing, coupled with favorable economic policies and incentives, further boost the demand for metal fabrication equipment in these regions. Market players can capitalize on these opportunities by expanding their presence, establishing partnerships with local firms, and offering tailored solutions that cater to specific market needs. Overall, the expanding industrial base and infrastructure development in emerging economies present promising growth prospects for the metal fabrication equipment market, positioning it for significant expansion in the foreseeable future.

Metal Fabrication Equipment Market Segmentation

The global metal fabrication equipment market has been divided into type, application, end user, and region.

- Type sector: cutting, machining, welding, bending, and others

- Application: job shops, automotive, aerospace & defense, mechanical application, and others

- Region: The Middle East and Africa, Europe, Latin America, North America, and Asia-Pacific

Metal Fabrication Equipment Market Regional Outlook

The metal fabrication equipment market exhibits varying dynamics across different regions. Asia-Pacific, led by countries like China, India, and Japan, dominates the global market share due to rapid industrialization and robust manufacturing activities. The region benefits from low labor costs, increasing foreign investments, and government initiatives supporting industrial growth. Investments in automotive, aerospace and infrastructure sectors fuel the demand for metal fabrication equipment in Asia-Pacific. North America and Europe are mature markets characterized by high adoption of advanced technologies and stringent quality standards. These regions witness steady demand driven by replacement of outdated machinery and investments in automation.

Metal Fabrication Equipment Market Players

Metal fabrication equipment companies profiled in the report include Amada, Colfax, Atlas Copco, Shenyang Machine Tool, FANUC Corp., Trumpf, DMG MORI, Okuma, Bystronic Laser, and BTD Manufacturing

Click here to buy the Premium Market Research report https://www.acumenresearchandconsulting.com/buy-now/0/939

Receive our personalized services and customization by clicking here https://www.acumenresearchandconsulting.com/request-customization/939

Mr. Richard Johnson

Acumen Research and Consulting

India: +918983225533

E-mail: [email protected]