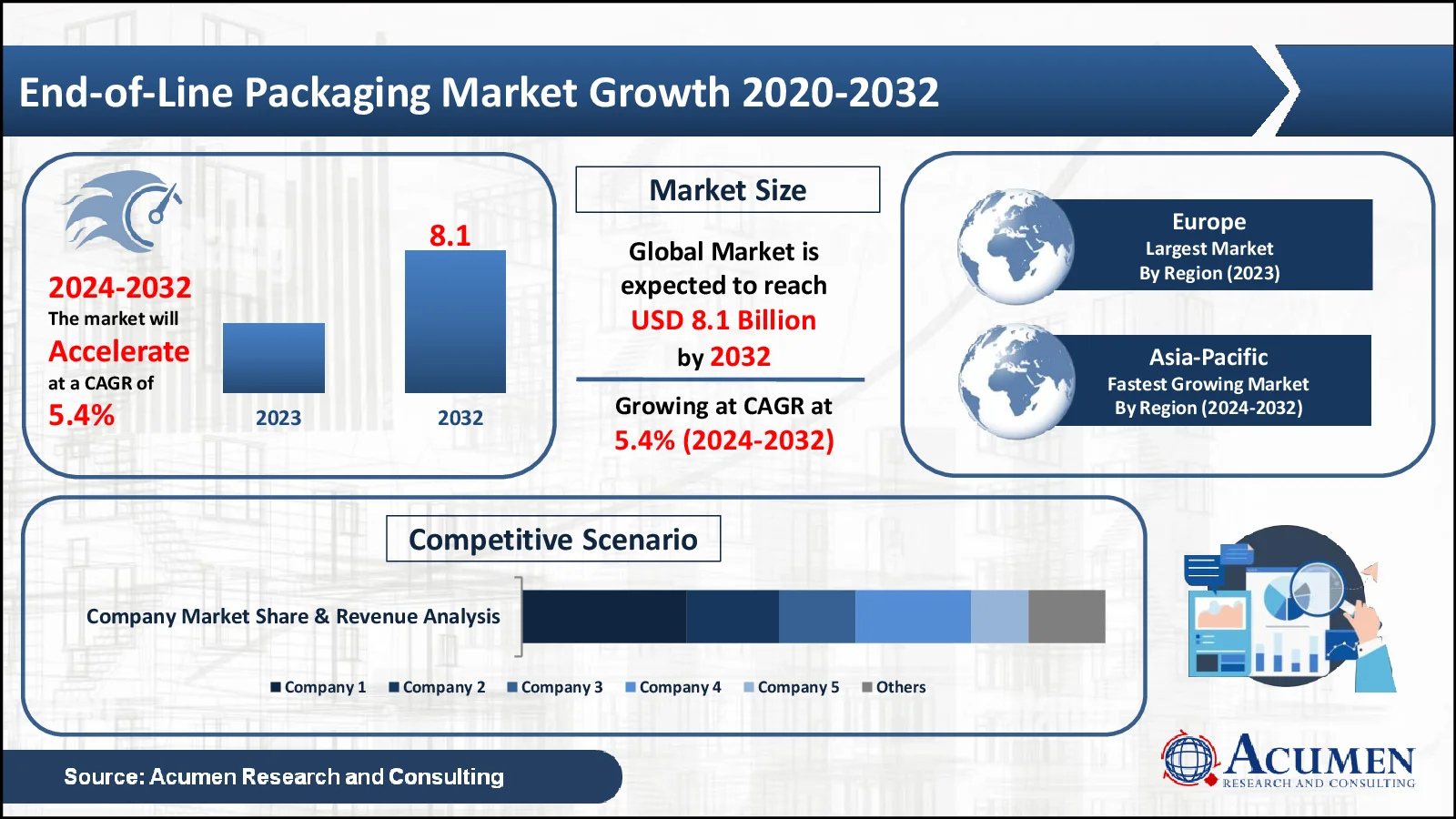

End-of-Line Packaging Market Size to Reach USD 8.1 Billion by 2032 growing at 5.4% CAGR - Exclusive Report by Acumen Research and Consulting

The End-of-Line Packaging Market, valued at USD 5.1 Billion in 2023, is anticipated to surpass USD 8.1 Billion by 2032, reflecting a projected CAGR of 5.4%

The end-of-line packaging market is expanding significantly as enterprises seek efficient and automated packaging solutions to fulfill rising consumer demand while minimizing operational costs. End-of-line packaging is the final stage of the packaging process in which products are ready for storage, transportation, or distribution. This market includes a wide range of solutions, including palletizing, case packing, sealing, and labeling. Its principal role is to guarantee that items are safely and efficiently packaged before they reach the market or end customers. The market's growth is being driven by factors such as increased demand for automation, technical developments in packaging systems, and a growing emphasis on lowering labor costs and boosting operational efficiency.

End-of-Line Packaging Market Statistics

- In 2023, the global end-of-line packaging market was valued at USD 5.1 billion

- The market is expected to grow at a stable annual pace of 5.4% from 2024 to 2032

- The Europe region accounts for 40% of the end-of-line packaging market

- Asia-Pacific is increasing at a CAGR of 6.2% in the end-of-line packaging market

- The automatic technology segment generates the largest income

- The palletizing function sector has notably contributed to revenue growth in the end-of-line packaging market

- Expanding packaging needs in emerging economies opens up new opportunities for participation

Access Table Of Content: https://www.acumenresearchandconsulting.com/table-of-content/end-of-line-packaging-market

End-of-Line Packaging Market Dynamics

Growing Demand for Automated Packaging Solutions Drives End-of-Line Packaging Market

The growing demand for automated packaging solutions is a major driver of the end-of-line packaging market. Food and beverage, pharmaceutical, automotive, and electronics industries are all increasingly using automation to optimize their packaging processes. Automation provides numerous benefits, including increased production, higher accuracy, lower labor costs, and fewer errors. Companies can ensure that their packing operations are consistent, speedier, and less prone to errors, resulting in increased efficiency and lower costs.

Automation has also gained traction due to its capacity to meet increasing customer demand for packaged goods. As e-commerce and retail channels increase, industries face increasing pressure to supply products promptly and in big quantities. Automated end-of-line packaging solutions enable businesses to keep up with production rates while preserving product quality. Furthermore, automation solutions provide flexibility, allowing producers to adapt to different packaging sizes and forms, which is critical in today's market, where customization and personalization are becoming more common.

Technological Advancements Boost the Efficiency of End-of-Line Packaging Systems

The use of sophisticated technologies like robotics, artificial intelligence (AI), and machine learning (ML) has substantially improved the efficiency and capacities of end-of-line packaging systems. Robotics, in particular, has altered the business by delivering highly accurate and adaptable solutions to operations such as palletizing, case packing, and labeling. Robotic systems are capable of performing complex packing tasks at fast speeds, reducing human interference and increasing operational efficiency.

Artificial intelligence and machine learning technologies are also crucial for improving the performance of end-of-line packaging equipment. These technologies allow systems to learn from previous data, anticipate potential problems, and alter operations in real time. For example, AI-powered packaging systems can analyze production data to optimize packing patterns, decrease waste, and increase overall process efficiency. The combination of these technologies enables businesses to achieve greater precision, reduce downtime, and improve product safety.

Sustainability Concerns Propel the Growth of Eco-friendly Packaging Solutions

Another key factor driving the end-of-line packaging market is an increased emphasis on sustainability and environmental concerns. Companies are under increasing pressure to develop environmentally friendly packaging solutions in order to meet regulatory obligations and consumer demand for sustainable products. End-of-line packaging systems are changing to incorporate environmentally friendly materials including recyclable, biodegradable, and compostable packaging.

Furthermore, technological improvements have resulted in the development of energy-efficient packaging machinery that uses less energy, produces less waste, and has a low environmental impact. Companies that invest in environmentally friendly end-of-line packaging solutions can lower their carbon footprint while meeting their customers' sustainability requirements.

End-of-Line Packaging Market Segmentation

The worldwide end-of-line packaging market is divides into 5 groups: Technology, Function, Order Type, and regional markets

- Technology: semi-automatic, and automatic

- Function: stretch wrapping, palletizing, labelling, integrated, carton erecting sealing, packing, and others

- Order Type: standard, and customized

- End Use: automotive, pharmaceutical. food and beverages, electronics & semiconductor, and others

- Regional: Latin America, North America, Asia-Pacific, the Middle East & Africa, and Europe

End-of-Line Packaging Market Regional Outlook

Europe is the largest end-of-line packaging market, owing to the existence of established businesses and the growing emphasis on sustainability. Companies in these locations are implementing eco-friendly packaging solutions and energy-efficient technology to meet regulatory requirements while also reducing environmental effect.

The end-of-line packaging market is expanding in several regions, with Asia Pacific emerging as the fastest-growing market. The region's fast industrialization, combined with the growing adoption of automation, is boosting demand for end-of-line packaging solutions. China, India, and Japan are leading the way in this expansion, thanks to booming industrial sectors and increased consumer demand for packaged goods.

End-of-Line Packaging Market Players

End-of-Line packaging companies profiled in the report include Pro Mach, Festo Corporation, Bosch Packaging Technology, DS Smith Plc, ABB Ltd., I.M.A. Industria Macchine Automatiche, MESPACK, Syntegon Technology GmbH, Krones AG, Combi Packaging Systems LLC, and Schneider Packaging Equipment Company.

Enquire Before Buying https://www.acumenresearchandconsulting.com/inquiry-before-buying/1378

Receive our personalized services and customization by clicking here https://www.acumenresearchandconsulting.com/request-customization/1378

Mr. Richard Johnson

Acumen Research and Consulting

India: +91 8983225533