Industrial Furnaces Market Size - Global Industry, Share, Analysis, Trends and Forecast 2023 - 2032

Select Access Type

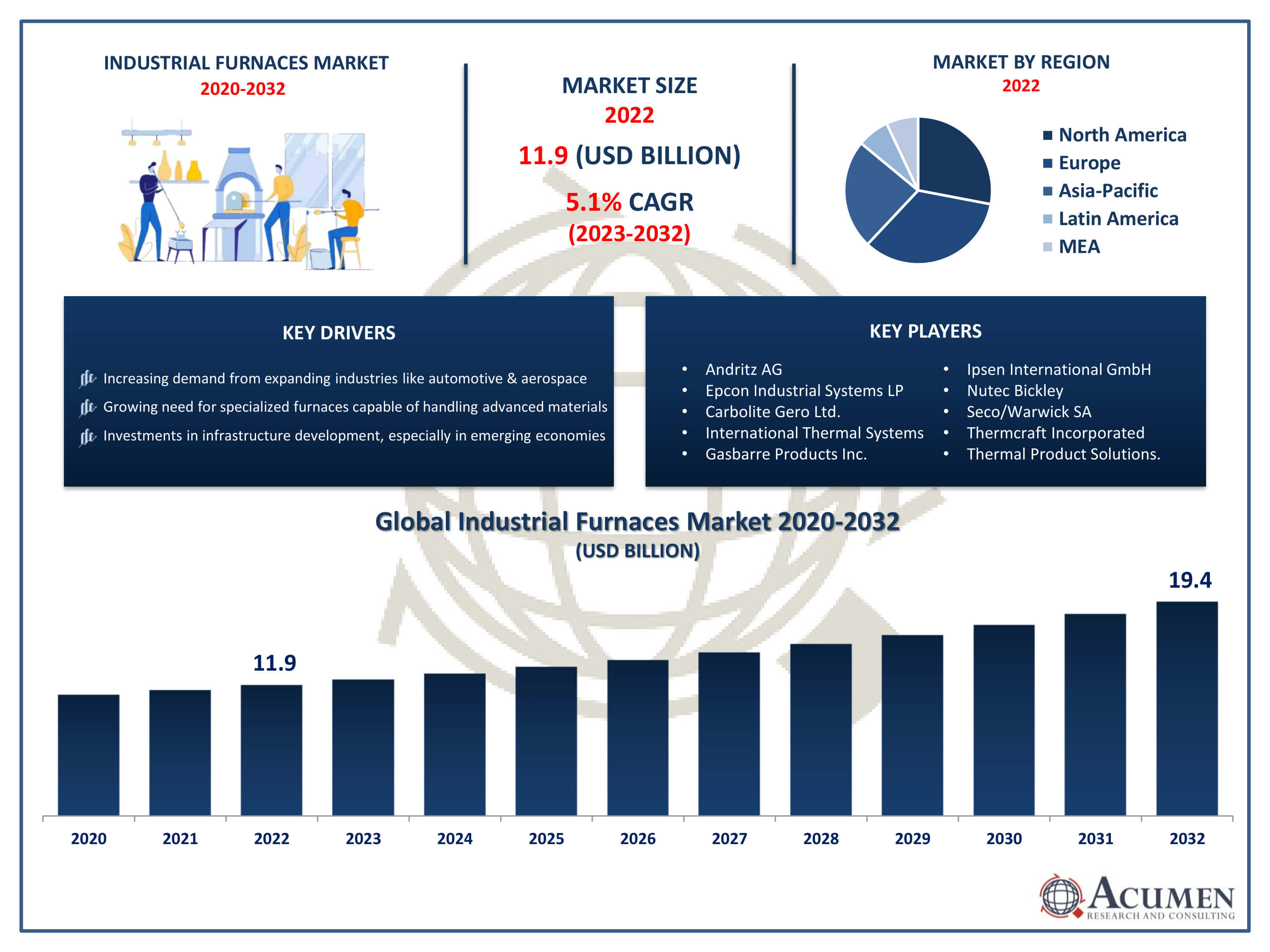

The Industrial Furnaces Market Size accounted for USD 11.9 Billion in 2022 and is projected to achieve a market size of USD 19.4 Billion by 2032 growing at a CAGR of 5.1% from 2023 to 2032.

Industrial Furnaces Market Highlights

- Global industrial furnaces market revenue is expected to increase by USD 19.4 billion by 2032, with a 5.1% CAGR from 2023 to 2032

- Europe region led with more than 40% of industrial furnaces market share in 2022

- Asia-Pacific industrial furnaces market growth will record a CAGR of more than 5.9% from 2023 to 2032

- By type, the gas and fuel operated segment captured more than 64% of revenue share in 2022.

- By end use, the metals & mining segment is projected to expand at the fastest CAGR over the projected period

- Increasing demand from expanding industries like automotive and aerospace, drives the industrial furnaces market value

The global market for industrial furnaces has witnessed steady growth over the years, driven by factors such as increasing industrialization, technological advancements, and growing demand across end-user industries. For instance, ECM Technologies recently launched the ECO furnace, an electrically heated system that enables a greater than 80% reduction in CO2 emissions. It also allows for higher temperatures, thereby increasing productivity through greater throughput. Furthermore, the ECO furnace provides a safer and more ergonomic environment without open flames and smoke, eliminating the risk of fire hazards. Additionally, the ECO furnace can be integrated into existing sealed quench or integral quench lines, using existing pits, conveyors, and peripheral equipment such as tempers and washers.

One of the key drivers for the growth of the industrial furnaces market is the expansion of industries like automotive, aerospace, and electronics, which heavily rely on heat treatment processes for the manufacturing of components and parts. Additionally, stringent regulations pertaining to energy efficiency and emissions have led to the development of more efficient and environmentally friendly furnace technologies, further boosting market growth. Moreover, the rising demand for specialized furnaces capable of handling advanced materials like composites and alloys has spurred innovation in the industry, opening up new avenues for market expansion.

Global Industrial Furnaces Market Trends

Market Drivers

- Increasing demand from expanding industries like automotive and aerospace

- Technological advancements leading to more energy-efficient and environmentally friendly furnace designs

- Growing need for specialized furnaces capable of handling advanced materials

- Investments in infrastructure development, especially in emerging economies

- Adoption of additive manufacturing techniques requiring post-processing heat treatment

Market Restraints

- Fluctuating raw material prices impacting manufacturing costs

- Intensifying competition among furnace manufacturers

Market Opportunities

- Integration of automation and digitalization in manufacturing processes

- Development of innovative furnace technologies catering to specific industry needs

Industrial Furnaces Market Report Coverage

| Market | Industrial Furnaces Market |

| Industrial Furnaces Market Size 2022 | USD 11.9 Billion |

| Industrial Furnaces Market Forecast 2032 | USD 19.4Billion |

| Industrial Furnaces Market CAGR During 2023 - 2032 | 5.1% |

| Industrial Furnaces Market Analysis Period | 2020 - 2032 |

| Industrial Furnaces Market Base Year |

2022 |

| Industrial Furnaces Market Forecast Data | 2023 - 2032 |

| Segments Covered | By Type, By Arrangement, By End Use, And By Geography |

| Regional Scope | North America, Europe, Asia Pacific, Latin America, and Middle East & Africa |

| Key Companies Profiled | Andritz AG, Epcon Industrial Systems LP, Carbolite Gero Ltd. (Dutch Verder Group), International Thermal Systems, Gasbarre Products Inc., Ipsen International GmbH, Nutec Bickley, LÖCHER Industrieofen- und Apparatebau GmbH, Seco/Warwick SA, Thermcraft Incorporated, ECM Technologies, and Thermal Product Solutions. |

| Report Coverage |

Market Trends, Drivers, Restraints, Competitive Analysis, Player Profiling, Covid-19 Analysis, Regulation Analysis |

Industrial furnaces are specialized heating devices utilized in a variety of manufacturing processes across numerous industries. These furnaces are designed to generate and maintain high temperatures required for tasks such as melting, forging, heat treating, and annealing of materials like metals, ceramics, glass, and composites. They come in diverse configurations ranging from batch furnaces suitable for small-scale production to continuous and tunnel furnaces used in large-scale industrial operations. Industrial furnaces play a critical role in enhancing the mechanical properties, durability, and overall quality of materials, thereby enabling the production of components and products with precise specifications and performance characteristics. The applications of industrial furnaces span across a wide array of industries including automotive, aerospace, electronics, construction, and metalworking. In the automotive sector, furnaces are used for heat treating components such as engine parts, gears, and transmission components to improve their strength, hardness, and wear resistance.

The industrial furnaces market has experienced robust growth in recent years, driven by a confluence of factors such as increasing industrialization, technological advancements, and the expansion of key end-user industries. As manufacturing sectors like automotive, aerospace, and electronics continue to thrive, the demand for industrial furnaces for various processes such as heat treatment, melting, and annealing has remained strong. Additionally, the push towards energy efficiency and environmental sustainability has led to the development of more efficient furnace designs, further fueling market growth. Moreover, emerging economies, particularly in regions like Asia-Pacific and Latin America, have become hotspots for industrial activity, driving the demand for industrial furnaces. Rapid urbanization and infrastructure development in these regions have spurred investments in manufacturing facilities, thereby boosting the market for industrial furnaces.

Furthermore, the incorporation of digitalization and smart technologies into industrial furnaces is transforming the industry. Advanced control systems, IoT-enabled devices, and real-time monitoring solutions improve the operational efficiency, precision, and safety of industrial furnaces. These smart technologies enable predictive maintenance, which lowers downtime and operational costs while increasing productivity. As a result, manufacturers are increasingly incorporating these innovations to remain competitive and meet the changing demands of modern industrial processes. For instance, on June 2023 – LyondellBasell made a significant announcement by signing an agreement (MOU) with Technip Energies and Chevron Phillips Chemical. This collaboration aims to investigate the development, construction, and operation of a demonstration unit based on Technip Energies' innovative electric steam cracking furnace technology. This cutting-edge eFurnace technology has the potential to transform the olefin cracking process by using renewable electricity as a heat source.

Industrial Furnaces Market Segmentation

The global industrial furnaces market segmentation is based on type, arrangement, end use, and geography.

Industrial Furnaces Market By Type

- Electrically Operated

- Gas and Fuel Operated

According to the industrial furnaces industry analysis, the gas and fuel-operated segment accounted for the largest market share in 2022. Gas and fuel-operated furnaces provide a reliable and controllable heat source for various industrial processes such as melting, forging, and heat treating. Their ability to achieve high temperatures quickly and maintain consistent heat levels makes them ideal for a wide range of applications across industries including metalworking, ceramics, and glass manufacturing. Moreover, the increasing focus on energy efficiency and sustainability has prompted industries to adopt gas and fuel-operated furnaces over traditional coal or electric-powered alternatives. Gas-fired furnaces, in particular, offer lower emissions and reduced energy consumption compared to coal-fired furnaces, aligning with stringent environmental regulations and sustainability goals. Additionally, advancements in burner technology and combustion systems have further enhanced the efficiency and performance of gas and fuel-operated furnaces, driving their popularity in the market.

Industrial Furnaces Market By Arrangement

- Box Type

- Tube or Clamshell Type

- Top Loading Furnace

- Bottom Loading & Car Bottom Furnace

- Others

In terms of arrangements, the box type segment is expected to witness significant growth in the coming years. Box type furnaces are characterized by their enclosed chamber design, which allows for controlled heating and processing of materials in a contained environment. These furnaces are commonly used for heat treatment, annealing, tempering, and aging processes in industries such as automotive, aerospace, electronics, and metalworking. One of the key factors contributing to the growth of the box type segment is the increasing demand for precision and consistency in manufacturing processes. Box type furnaces offer precise temperature control and uniform heating throughout the chamber, ensuring the quality and integrity of processed materials. Additionally, advancements in insulation materials and heating elements have improved the energy efficiency and performance of box type furnaces, further driving their adoption across industries.

Industrial Furnaces Market By End Use

- Oil & Gas

- Chemicals

- Metals & Mining

- Transportation

- Others

According to the industrial furnaces market forecast, the metals & mining segment is expected to witness significant growth in the coming years. Industrial furnaces play a crucial role in the metals and mining sector by facilitating processes such as smelting, refining, alloying, and heat treatment. These furnaces are essential for melting metals from ores, scrap, or ingots, and subsequently shaping them into desired forms such as bars, sheets, or components. One of the key drivers of growth in this segment is the rising demand for advanced materials and alloys with enhanced properties such as strength, durability, and corrosion resistance. Industrial furnaces enable the precise control of temperature and atmosphere conditions necessary for the production of high-quality metals and alloys meeting stringent industry standards. Moreover, technological advancements in furnace design, automation, and process control have led to improvements in efficiency, productivity, and cost-effectiveness, driving further adoption in the metals and mining sector.

Industrial Furnaces Market Regional Outlook

North America

- U.S.

- Canada

Europe

- U.K.

- Germany

- France

- Spain

- Rest of Europe

Asia-Pacific

- India

- Japan

- China

- Australia

- South Korea

- Rest of Asia-Pacific

Latin America

- Brazil

- Mexico

- Rest of Latin America

The Middle East & Africa

- South Africa

- GCC Countries

- Rest of the Middle East & Africa (ME&A)

Industrial Furnaces Market Regional Analysis

Europe stands out as a dominating region in the industrial furnaces market due to several key factors that contribute to its leadership position in the industry. One significant factor is Europe's strong manufacturing base across various sectors including automotive, aerospace, chemicals, and metallurgy. These industries heavily rely on industrial furnaces for processes such as heat treatment, casting, forging, and annealing, driving substantial demand for furnace equipment and services in the region. Moreover, Europe boasts a long history of technological innovation and engineering excellence, particularly in furnace manufacturing and materials processing. European furnace manufacturers are renowned for their expertise in developing high-quality, precision-engineered furnaces that meet the demanding requirements of modern industrial applications. This reputation for quality and reliability has enabled European companies to capture a significant share of the global market and establish themselves as leaders in furnace technology and solutions. Additionally, Europe's commitment to sustainability and environmental stewardship has led to the development and adoption of energy-efficient and eco-friendly furnace technologies. Stringent regulations and emissions standards in the region have incentivized industries to invest in cleaner and more efficient heating solutions, further driving demand for advanced industrial furnaces.

Industrial Furnaces Market Player

Some of the top industrial furnaces market companies offered in the professional report include Andritz AG, Epcon Industrial Systems LP, Carbolite Gero Ltd. (Dutch Verder Group), International Thermal Systems, Gasbarre Products Inc., Ipsen International GmbH, Nutec Bickley, LÖCHER Industrieofen- und Apparatebau GmbH, Seco/Warwick SA, Thermcraft Incorporated, ECM Technologies, and Thermal Product Solutions.