Electronics Conformal Coating Market Size - Global Industry, Share, Analysis, Trends and Forecast 2023 - 2032

Select Access Type

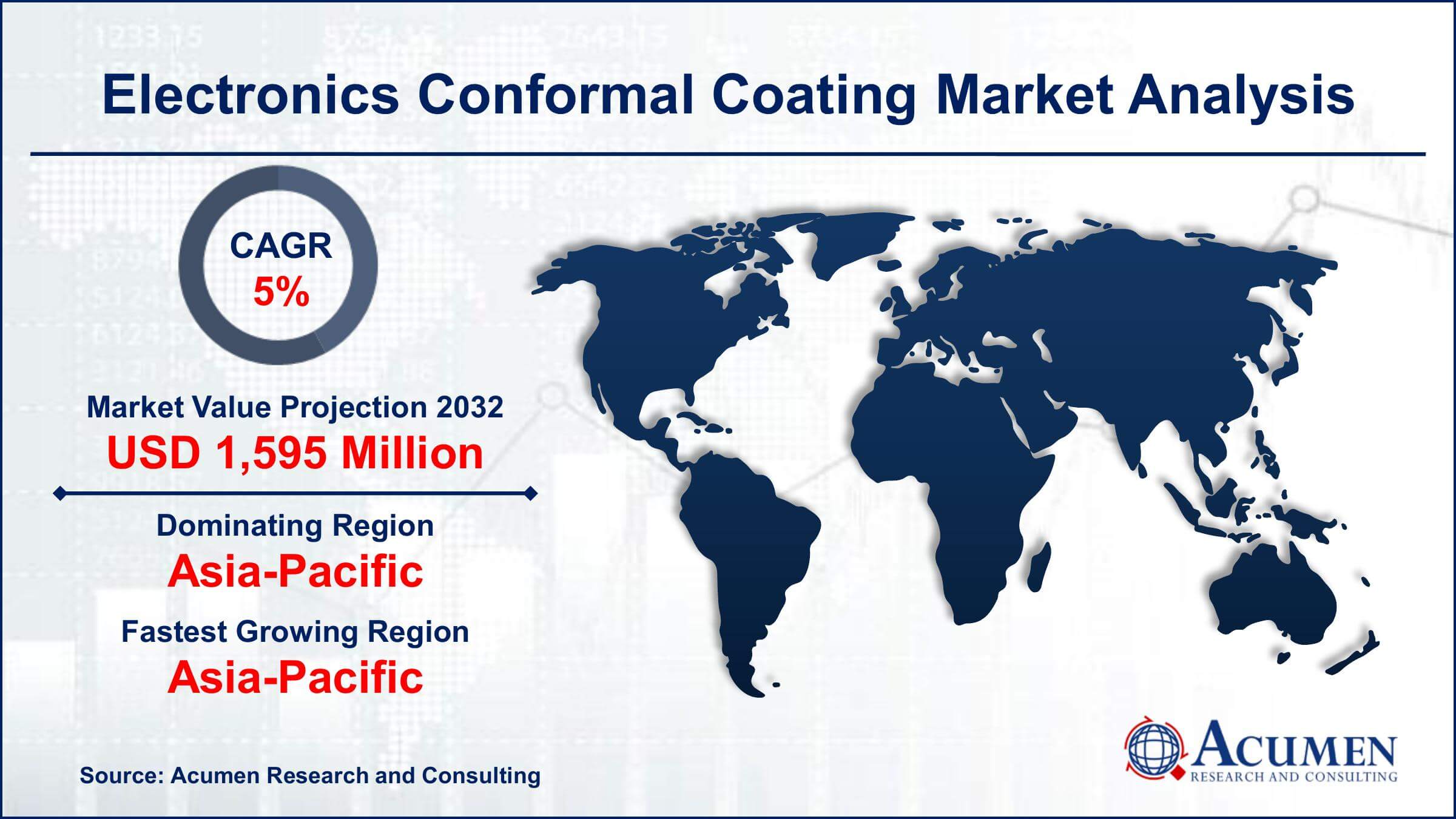

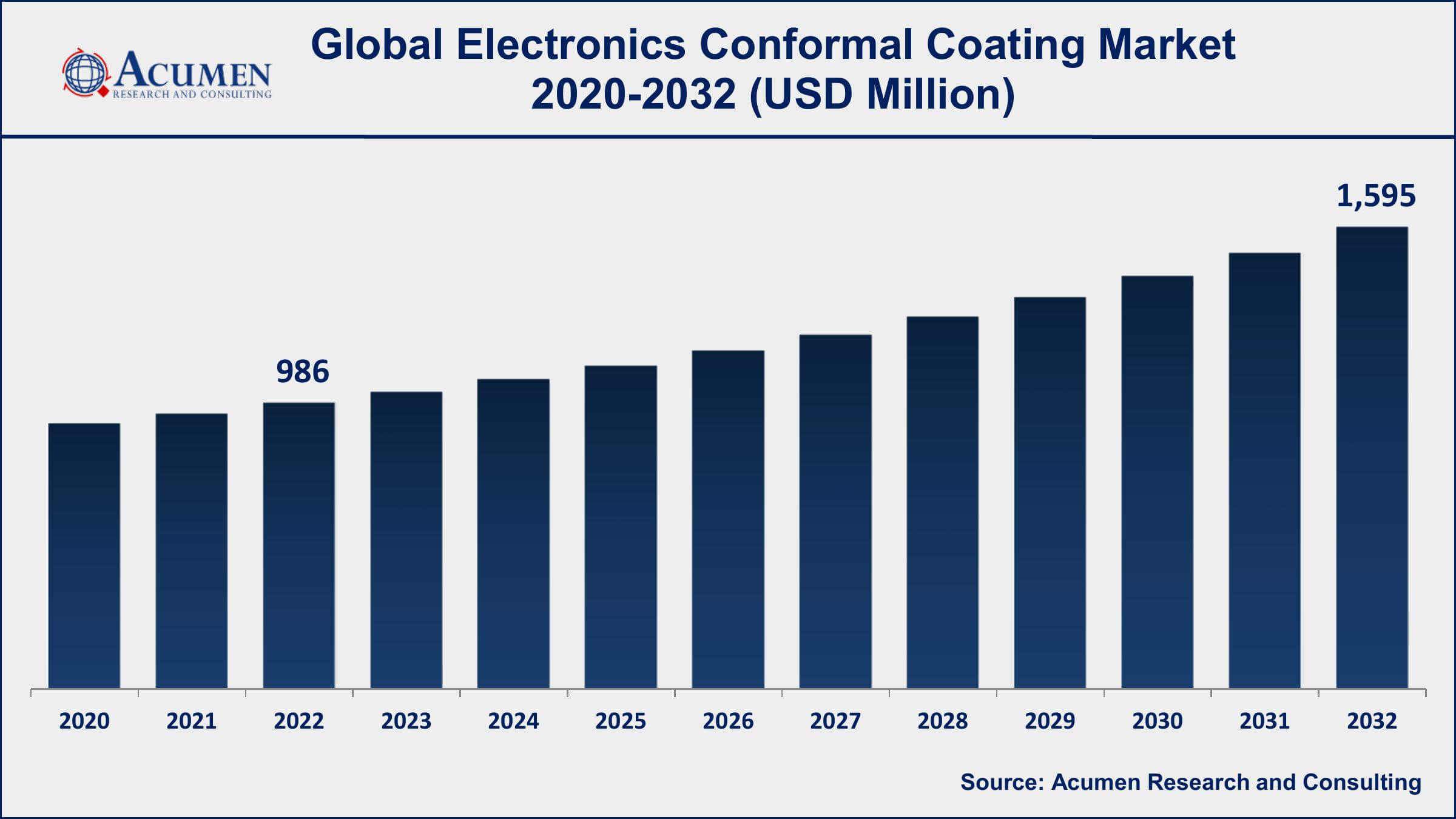

The Global Electronics Conformal Coating Market Size accounted for USD 986 Million in 2022 and is projected to achieve a market size of USD 1,595 Million by 2032 growing at a CAGR of 5% from 2023 to 2032.

Electronics Conformal Coating Market Highlights

- Global electronics conformal coating market revenue is expected to increase by USD 1,595 Million by 2032, with a 5% CAGR from 2023 to 2032

- Asia-Pacific region led with more than 46% of electronics conformal coating market share in 2022

- According to research, the global consumer electronics market was valued at around 1.04 trillion USD in 2020 and is projected to reach approximately 1.5 trillion USD by 2026

- According to the United Nations University, the world generated approximately 53.6 million metric tons of e-waste in 2019, and this figure is expected to reach 74.7 million metric tons by 2030

- By type, the acrylic segment captured the largest market share in 2022

- Increasing miniaturization and complexity of electronic devices, drives the electronics conformal coating market value

Electronics conformal coating refers to a protective layer or film that is applied to electronic components and circuit boards to protect them from environmental factors such as moisture, dust, chemicals, and temperature variations. It is typically made of materials such as acrylics, silicones, polyurethanes, or epoxy resins. The conformal coating forms a barrier that prevents corrosion, electrical shorts, and other types of damage that can be caused by exposure to harsh conditions.

The market for electronics conformal coating has been experiencing steady growth in recent years. This growth can be attributed to several factors. Firstly, with the increasing complexity and miniaturization of electronic devices, there is a greater need for effective protection against environmental factors. Conformal coatings provide a reliable solution to safeguard delicate electronic components and ensure their long-term reliability. Additionally, the expansion of industries such as automotive, aerospace, consumer electronics, and medical devices has contributed to the market growth. These sectors rely heavily on electronic components, and the demand for conformal coating is driven by the need to enhance the performance and durability of these devices.

Global Electronics Conformal Coating Market Trends

Market Drivers

- Increasing miniaturization and complexity of electronic devices

- Growing demand for reliable protection against environmental factors

- Expansion of industries such as automotive, aerospace, consumer electronics, and medical devices

- Rising awareness about the importance of conformal coating in preventing premature failures

Market Restraints

- High costs associated with conformal coating materials and application processes

- Challenges in achieving uniform coating thickness and coverage

Market Opportunities

- Adoption of automated coating equipment for enhanced efficiency and precision

- Growing focus on eco-friendly and sustainable coating solutions

Electronics Conformal Coating Market Report Coverage

| Market | Electronics Conformal Coating Market |

| Electronics Conformal Coating Market Size 2022 | USD 986 Million |

| Electronics Conformal Coating Market Forecast 2032 | USD 1,595 Million |

| Electronics Conformal Coating Market CAGR During 2023 - 2032 | 5% |

| Electronics Conformal Coating Market Analysis Period | 2020 - 2032 |

| Electronics Conformal Coating Market Base Year | 2022 |

| Electronics Conformal Coating Market Forecast Data | 2023 - 2032 |

| Segments Covered | By Type, By Technology, By Application, By Industry Vertical, And By Geography |

| Regional Scope | North America, Europe, Asia Pacific, Latin America, and Middle East & Africa |

| Key Companies Profiled | Henkel AG & Co. KGaA, Dow Corning Corporation, Chase Corporation, H.B. Fuller Company, Electrolube, Shin-Etsu Chemical Co., Ltd., MG Chemicals Ltd., Dymax Corporation, Europlasma NV, ACC Silicones Ltd., Specialty Coating Systems, Inc., and Aalpha Conformal Coatings. |

| Report Coverage |

Market Trends, Drivers, Restraints, Competitive Analysis, Player Profiling, Covid-19 Analysis, Regulation Analysis |

Electronics conformal coating is a protective coating applied to electronic components and printed circuit boards (PCBs) to safeguard them against environmental factors. The coating material is typically a thin layer of polymer or resin that conforms to the shape of the component or PCB, creating a protective barrier. The primary purpose of conformal coating is to prevent moisture, dust, chemicals, and other contaminants from coming into contact with the sensitive electronic parts, which can cause corrosion, electrical shorts, or malfunctions. The application of conformal coating offers several benefits in the field of electronics. Firstly, it provides protection against moisture, which is a common cause of electrical failures. Moisture can enter electronic devices through humidity, condensation, or exposure to liquids, leading to corrosion of metal components and degradation of insulation materials. Conformal coating acts as a moisture barrier, preventing these issues and improving the reliability and lifespan of electronic devices.

The electronics conformal coating market has been experiencing significant growth in recent years and is expected to continue its upward trajectory. Several factors contribute to this market growth. Firstly, the increasing demand for electronic devices across various industries such as automotive, aerospace, consumer electronics, and healthcare is a key driver. As the complexity and miniaturization of electronic components continue to advance, there is a growing need to protect these sensitive components from environmental factors. Conformal coatings provide a reliable solution by creating a protective barrier against moisture, dust, chemicals, and temperature variations, ensuring the longevity and reliability of the devices.

Electronics Conformal Coating Market Segmentation

The global electronics conformal coating market segmentation is based on type, technology, application, industry vertical, and geography.

Electronics Conformal Coating Market By Type

- Acrylic

- Silicone

- Hybrid

- Polyurethane

- Epoxy

According to the electronics conformal coating industry analysis, the acrylic segment accounted for the largest market share in 2022. Acrylic conformal coatings are widely used due to their excellent protective properties, ease of application, and cost-effectiveness. One of the key factors driving the growth of the acrylic segment is the increasing demand for electronic devices across various industries. Acrylic conformal coatings provide effective protection against environmental factors such as moisture, chemicals, dust, and temperature fluctuations. As industries such as automotive, aerospace, consumer electronics, and medical devices continue to expand, there is a growing need for reliable conformal coatings to ensure the longevity and reliability of electronic components.

Electronics Conformal Coating Market By Technology

- Solvent Based

- UV Cured

- Water Based

In terms of technologies, the solvent based segment is expected to witness significant growth in the coming years. Solvent-based conformal coatings are formulated with organic solvents, which aid in the application and curing process. These coatings offer various benefits that contribute to their market growth. One of the key factors driving the growth of the solvent-based segment is their excellent compatibility with a wide range of substrates. They provide good adhesion to different materials used in electronic components and circuit boards, ensuring reliable protection. This compatibility allows solvent-based coatings to be used across various industries, including automotive, aerospace, telecommunications, and consumer electronics.

Electronics Conformal Coating Market By Application

- Appearance

- Thermal Shock

- Moisture & Insulation Resistance

- Flammability

- UV Fluorescence

- Adhesive

According to the electronics conformal coating market forecast, the appearance segment is expected to witness significant growth in the coming years. This growth is driven by the increasing importance of aesthetics in electronic devices. Conformal coatings not only provide protection but also contribute to the overall appearance and cosmetic appeal of electronic components and circuit boards. The growing demand for visually appealing electronic devices, especially in consumer electronics and automotive sectors, is a key factor driving the growth of the appearance segment. Manufacturers are placing greater emphasis on the visual design and finish of their products to attract consumers. Conformal coatings play a vital role in achieving the desired appearance by providing a smooth, uniform, and visually pleasing surface finish.

Electronics Conformal Coating Market By Industry Vertical

- Consumer Electronics

- Aerospace & Defense

- Marine

- Industrial & Telecommunication

- Automotive

- Medical

Based on the industry vertical, the consumer electronics segment is expected to continue its growth trajectory in the coming years. Consumer electronics encompass a wide range of devices such as smartphones, tablets, wearables, gaming consoles, and home appliances. These devices are increasingly integrated into our daily lives, and their reliability and durability are paramount. Conformal coatings play a vital role in protecting sensitive electronic components within consumer electronic devices from environmental factors such as moisture, dust, chemicals, and temperature variations. As the demand for consumer electronics continues to rise, manufacturers are increasingly incorporating conformal coatings to ensure the longevity and reliability of these devices, driving the growth of the consumer electronics segment in the conformal coating market.

Electronics Conformal Coating Market Regional Outlook

North America

- U.S.

- Canada

Europe

- U.K.

- Germany

- France

- Spain

- Rest of Europe

Asia-Pacific

- India

- Japan

- China

- Australia

- South Korea

- Rest of Asia-Pacific

Latin America

- Brazil

- Mexico

- Rest of Latin America

The Middle East & Africa

- South Africa

- GCC Countries

- Rest of the Middle East & Africa (ME&A)

Electronics Conformal Coating Market Regional Analysis

The Asia-Pacific region dominates the electronics conformal coating market for several key reasons. Firstly, Asia-Pacific is home to some of the largest electronics manufacturing hubs in the world, including China, Japan, South Korea, and Taiwan. These countries are major producers of consumer electronics, automotive electronics, and other electronic devices, driving the demand for conformal coatings. The presence of a vast manufacturing ecosystem and supply chain in the region supports the electronics conformal coating market growth. Moreover, the Asia-Pacific region has experienced rapid industrialization and economic growth, leading to increased investments in infrastructure development, automotive production, and consumer electronics manufacturing. The rising disposable incomes and growing middle-class population in countries like China and India have resulted in higher consumer spending on electronic devices, further bolstering the demand for conformal coatings.

Electronics Conformal Coating Market Player

Some of the top electronics conformal coating market companies offered in the professional report include Henkel AG & Co. KGaA, Dow Corning Corporation, Chase Corporation, H.B. Fuller Company, Electrolube, Shin-Etsu Chemical Co., Ltd., MG Chemicals Ltd., Dymax Corporation, Europlasma NV, ACC Silicones Ltd., Specialty Coating Systems, Inc., and Aalpha Conformal Coatings.